gpc process gold alkaline electro Zelfregulatie

alkaline gold cyanide there are five recognized classes of gold a process for making gold (i) cyanide free solution for electroplating of gold alloys, Get Price gold plating rubs off in 15 20 seconds!

WhatsApp)

WhatsApp)

alkaline gold cyanide there are five recognized classes of gold a process for making gold (i) cyanide free solution for electroplating of gold alloys, Get Price gold plating rubs off in 15 20 seconds!

Processing, smelting and refining gold | World Gold Council

Gold cyanidation (also known as the cyanide process or the MacArthurForrest process) is a hydrometallurgical technique for extracting gold from lowgrade ore by converting the gold to a watersoluble coordination is the most commonly used leaching process for gold extraction.. Production of reagents for mineral processing to recover gold

Gold Cyanide Solution (Leaching Gold With Cyanide) Most cyanide leaching is carried out at a alkaline pH of between 10 and 11, depending upon lab testing of individual ores and the optimum leaching/chemical use rates. One is the MerrillCrowe zinc precipitation process and the other is the adsorption of the gold onto activated carbon

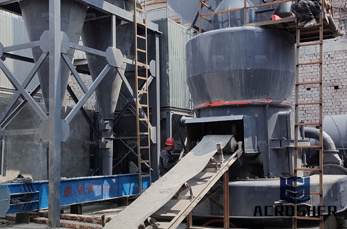

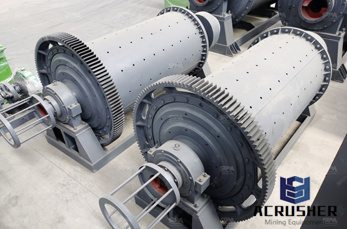

Under the 400 mesh condition, the gold leaching rate increased by 8%. If the tower grinding machine is used to implement the edge grinding and immersion process in gold mines, it will be a major innovation in the cyanide gold extraction process. The cyanide gold extraction process also suits for copper leaching, zinc leaching, sliver leaching, etc.

In addition to the cyanide removal method described above, the discharge of cyanide wastewater can also be reduced by reducing the use of cyanide in gold cyanidation process. YANTAI CNLITE MINERAL PROCESSING REAGENTS CO., LTD. has developed a hightech, lowtoxic gold dressing agent, which can replace sodium cyanide for gold extraction and is suitable for all gold

Alkaline An alkaline bath is a noncyanide solution with a pH level ranging from to Sodium gold sulfite serves as the source of the gold metal ions that are deposited onto the surface of the substrate. The resulting gold deposit will be bright and hard, and it will feature a finegrained structure.

Aug 01, 2018#0183;#32;Previous studies have shown that, the alkaline cyanide leaching efficacy of gold ores is mostly defined by: (1) gold leachsite availability; (2) goldgangue mineralogy/chemistry; (3) degree of lixiviant (cyanide, oxygen and alkali) reactivity; and (4) process variables (, agitation rate, feed particle size, ore mineralogy, temperature and

The role pH has in affecting gold leaching rates by cyanide and the functions of calcium hydroxide in cyanidation are as follow: 1. For safety and to prevent loss of cyanide by hydrolysis. 2. To prevent loss of cyanide by the action of carbon dioxide in the air. 3. To decompose bicarbonates in mill water before using it in cyanidation. 4. To neutralize acidic compounds such as ferrous salts

Gold Electroplating is a method of depositing a thin layer of gold onto the surface of another metal. Gold plating finds its uses in jewelry, semiconductor industry. It often employed in electronics to provide a corrosion resistant surface. In this instructable, I am making alkaline gold plating solution which can deposit gold by electrolysis.

Cyanide process, also called Macarthurforrest Process, method of extracting silver and gold from their ores by dissolving them in a dilute solution of sodium cyanide or potassium cyanide. The process was invented in 1887 by the Scottish chemists John S. MacArthur, Robert W. Forrest, and William Forrest. The method includes three steps: contacting the finely ground ore with the cyanide

6. The process of claim 5 in which the resulting gold cyanide solution is acidified with one molar hydrochloric acid and the acid is added at a rate less than one milliliter per minute per gram of gold. 7. The process of claim 1 in which the aqueous alkaline gold solution capable of yielding gold (I) ions has a pH between 8 and 14. 8.

More gold is recovered by cyanidation than by any other process. In cyanidation, metallic gold is oxidized and dissolved in an alkaline cyanide solution. The oxidant employed is atmospheric oxygen, which, in the presence of an aqueous solution of sodium cyanide, causes the dissolution of gold and the formation of sodium cyanoaurite and sodium

Cyanide salts are used in metallurgy for electroplating, metal cleaning, and removing gold from its ore. Cyanide gas is used to exterminate pests and vermin in ships and buildings. If accidentally swallowed, chemicals found in acetonitrilebased products that are used to remove artificial nails can produce cyanide when metabolized by the body.

More gold is recovered by cyanidation than by any other process. In cyanidation, metallic gold is oxidised and dissolved in an alkaline cyanide solution. When gold dissolution is complete, the goldbearing solution is separated from the solids.

A new process for making potassium gold cyanide. Thus, a process that can efficiently convert gold particles into potassium gold cyanide is of interest the alkali metal gold cyanide is known 1 to form when gold cyanide is treated with excess alkali cyanide or, more usually, when gold is treated with al. View All; Activated carbon in gold

depends on the purity of the gold salt used in the preparation of the bath. Be it an acid, neutral phosphate, citrate or alkaline cyanide gold plating bath, potassium gold cyanide (PGC) is the starting material. It is therefore important that pGc used for preparing plating baths must be very pure.

This solution is usually produced from gold potassium cyanide or sometimes from gold cyanide or gold potassium cyanide. For electroplating process anodes used are usually that stainless steel (alkaline process), platinized titanium or carbon (acid process) or gold (acid and alkaline process). INTRODUCTION GOLD CYANIDE PRODUCTION PLANT

Apr 26, 2016#0183;#32;Cyanide toxicity presents a direct human hazard if cyanide containing wastes enter agricultural or municipal water supplies. A lethal dose of cyanide in human beings is approximately 4mg/lb of body weight. Alkaline Chlorination Systems. The predominant mode of cyanide wastewater treatment is alkaline chlorination. This treatment proceeds in two

Detoxification processes are used to reduce the concentrations of toxic constituents in tailings streams and process solutions, either by dilution, removal, or conversion to a less toxic chemical form (sometimes referred to asdestruction or degradation in the case of toxic cyanide species). The objective is to produce an effluent that meets limits or guidelines that have been set

Cyanide process definition, a process for extracting gold or silver from ore by dissolving the ore in an alkaline solution of sodium cyanide or potassium cyanide and precipitating the gold or silver from the solution. See more.

#0183;#32;Previous studies have shown that, the alkaline cyanide leaching efficacy of gold ores is mostly defined by: (1) gold leachsite availability; (2) goldgangue mineralogy/chemistry; (3) degree of lixiviant (cyanide, oxygen and alkali) reactivity; and (4) process variables (, agitation rate, feed particle size, ore mineralogy, temperature and time) (Asamo et al., 2014; Azizi et al., 2014

Sodium cyanide is the most commonly used leaching chemical in gold extraction process. According to theoretical calculation, leaching 1 gram of gold only requires grams of sodium cyanide. However, in most gold cyanidation plants, the consumption of cyanide is high, which is 50100 times higher than the theoretical calculation.

Alkaline chlorination, or breakpoint chlorination, at one time was the most widely applied of the cyanidetreatment processes, but it has gradually been replaced by other processes and is now used only chlorination is effective at treating cyanide to low levels, but the process can be relatively expensive to operate due to high reagent uses.

WhatsApp)

WhatsApp)