How Vertical Grinding Mills Work (Coal Pulverizer

14/06/2019#0183;#32;Learn about vertical grinding mills and coal pulverizers! We look at all of the vertical grinding mills main components, how it works and some of its design...

WhatsApp)

WhatsApp)

14/06/2019#0183;#32;Learn about vertical grinding mills and coal pulverizers! We look at all of the vertical grinding mills main components, how it works and some of its design...

grinding mill installation procedure As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including quarry, aggregate, and different kinds of minerals.

procedure installation of vertical grinding mill. The vertical milling machine is a precision tool used for shaping and fabrication by the removal of stock typically from metallic work pieces plastics and other materials can also be machined on the mill depending upon tooling and material mill controls may be manually operated, computer numerical controlled cnc, or a combination of both

installation of vertical grinding mill in lithuania. LM Vertical Mill 10 Comments Super User 3 Tags High drying efficiency Low running cost Good environmental effect LM Vertical Mill integrates crushing drying grinding classifying and conveying together and it is specialized in processing nonmetallic minerals pulverized coal and slag.

16/01/2019#0183;#32;Vertical Roller Mill Install the operating procedures and maintenance Minging machine is an important auxiliary equipment, mainly used for mining, smelting, coal, building materials, refractory materials, light industry, chemical industry, medicine, food and other industries.

4 Advantages of Polysius roller mills at a glance: xHigh operating reliability and availability, as well as easy system handling, due to the fact that grinding, drying and separation all take place in a single compact unit. xConsistently high product quality with minimum

procedure installation of vertical grinding mill. LM series Vertical Grinding Mill LM series vertical grinding mill is one advanced powder making mill which is developed through many construction work and installation and commissioning etc with

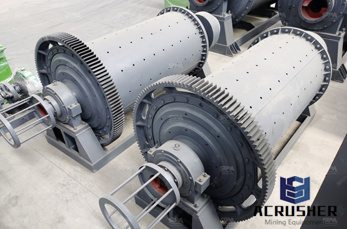

Procedure For Ins Tallation Of Ball Mill India. Vertical roller mills for cement grinding international cement review ball mill maintenance amp installation procedure 911 metallurgist may 30 2017 am sure your ball mill is considered the finest possible grinding mill available as such you will find it is designed and constructed according to

Metallurgical ContentBall Mill Maintenance ManualOn Mill Installation and MaintenanceBall Mill Concrete FoundationsGrinding Mill FOUNDATIONGROUTINGBall Mill Sole Plate Am sure your Ball Mill is considered the finest possible grinding mill available. As such you will find it is designed and constructed according to heavy duty specifications. It is designed along sound engineering principles

Erection Procedure For Vertical Roller Mill. Vertical roller mill for cement grindingn the cement grinding process, grinding system using the tube mill is widely recently, especially from 1980s, grinding system using the vertical roller mill, 4 the installation area of the vertical roller mill is about half of tube mill grinding read more.

The Loesche coal grinding mill range is divided into two serial types: Small twin mills constructed to individual specifications (LM D to LM D), with table diameters from 1,200 to 2,000 mm. Larger mills with two, three and four rollers and modular structures (LM D to LM D), with table diameters from 2,100 to 4,300 mm.

installation for vertical grinding mill in ireland. procedure for relocating a vertical raw mill in cement industry Cement grinding Vertical roller mills versus ball mills cement industry the ball mill was really an epochmaking breakthrough as for almost 80 years it was the predominant mill for grinding of raw materials and coal and still today is the most used mill for cement grinding

procedure installation of vertical grinding mill Grinding Mill . CEMENT GRINDING IN A VERTICAL ROLLER MILLBall Mill This page is about the cement grinding in a vertical roller mill, Installation, Design, Operation, Efficiency. #187;More detailed

Follow correct clamping procedures. Keep overhangs as small as possible and check workpiece is secure. Set the correct speed to suit the cutter diameter, the depth of cut and the material. ENDING OPERATIONS AND CLEANING UP. Switch off the machine when work completed. Remove milling cutters and store them safely.

installation for vertical grinding mill prosedurre installation of vertical grinding mill, procedure installation of vertical installation for vertical grinding mill Chat Now

How To Commissioning Vertical Cement Mill. Commissioning Procedure For Gold Mills. Ball mill and grinding circuit preparation for startup the following items must be checked before the equipment in the grinding circuit is started check the ore slot feeder for obstruction or hangups check the ball mill belt feeder for undue buildup of material check oil level in ball mill lube oil tanksget price

There is a large gap between the tip speed and power intensity of the lowspeed vertical mills and the highspeed horizontal mills. The VXP mill bridges the gap between highspeed and lowspeed mills. The VXPmills are designed for fine and ultra fine grinding applications. In practice, the mill performs best when the feed has a normal distribution.

WhatsApp)

WhatsApp)