formula for critical speed of ball mill

Critical speed of the mill lt;ulgt;lt;ligt;The faster the mill is rotated,the higher of the mill and is given by formula: lt;/ligt;lt;/ulgt; N = R N = Critical speed . Get Price

WhatsApp)

WhatsApp)

Critical speed of the mill lt;ulgt;lt;ligt;The faster the mill is rotated,the higher of the mill and is given by formula: lt;/ligt;lt;/ulgt; N = R N = Critical speed . Get Price

The critical speed of the mill, amp; c, is defined as the speed at which a single ball will just remain against the wall for a full cycle. At the top of the cycle =0 and Fc Fg () mp amp; 2 cDm 2 mpg () amp; c 2g Dm 1/2 () The critical speed is usually expressed in terms of the number of revolutions per second Nc amp; c 2 1 2 2g Dm 1/2 (2#215;)1/2

Effect of Mill Speed on the Energy Input In this experiment the overall motion of the assembly of 62 balls of two different sizes was studied. The mill was rotated at 50, 62, 75 and 90% of the critical speed. Six lifter bars of rectangular crosssection were used at equal spacing. The overall motion of the balls at the end of five revolutions is shown in Figure 4. As can be seen from the

Critical speed formula of cement ball mill critical speed formula of cement ball mill ball mill critical speed mineral processing amp a ball mill critical speed actually ball, rod, ag or sag is the speed at which the centrifugal forces equal gravitational forces at the mill shells inside surface and no balls will fall from its position onto the shell

Mill speed rpm GM in I chamber 107 t Critical speed 76 % GM in II chamber 217 t Separator Sepax 450M222 Separator Cyclone 4 nos. Separator motor 300 kW Separator Fan 248300 m 3/h ESP Fan 74100 m 3/h 497 mmwg 375 mmwg 500 kW 110 kW Bag Filter Fan 21720 m

2 click here to Download the Most Important 13 Books in Cement Industry 3 Ball Mill Calculation Formulas. BALL MILL CHARGE BALL MILL POWER; BALL MILL CRITICAL SPEED; 4 click here to Download the Most Important 13 Books in Cement Industry 5 click here to Download the Most Important 13 Books in Cement Industry

At what speed will the mill have to be run if the 100 mm balls are replaced by 50 mm balls, all the other conditions remaining the same? Calculations: The critical speed of ball mill is given by, where R = radius of ball mill; r = radius of ball. For R = 1000 mm and r = 50 mm, n c = rpm. But the mill is operated at a speed of 15 rpm.

Ball Mill Operating Speed Mechanical Operations Solved Problems m

In most cases, the ideal mill speed will have the media tumbling from the top of the pile (the shoulder) to the bottom (the toe) with many impacts along the way. The ideal mill speed is usually somewhere between 55% to 75% of critical speed. Critical Mill Speed. Critical Speed (left) is the speed at which the outer layer of media centrifuges against the wall. Second Critical Speed (middle) is the speed at which

The point where the mill becomes a centrifuge is called the quot;Critical Speedquot;, and ball mills usually operate at 65% to 75% of the critical speed. Ball Mills are generally used to grind material 1/4 inch and finer, down to the particle size of 20 to 75 microns.

A Ball Mill Critical Speed (actually ball, rod, AG or SAG) is the speed at which the centrifugal forces equal gravitational forces at the mill shells inside surface and no balls will fall from its position onto the shell. The imagery below helps explain what goes on inside a mill as speed varies. Use our online formula The mill speed is typically defined as the percent of the Theoretical

Calculating Mill Drive RPMs: Is Your Mill Up to Speed? By Robert A. Sladky Vice President Tube Mill Engineering Many quot;Wquot; style mills that have the ability to shim up the bottom driven shafts in each section to maintain metal line after tooling is reworked, and are many times also equipped with a individual motor drive in each of the three sections as illustrated below.

Cement Ball Mill Critical Speed Formula. Cement plant ball mills critical speed formulae ball mill types and formula emotion the power consumption calculation of a ball drum mill idosi full text of holderbank cement engineering book internet archive high filling degrees and high percentage of critical speed lead to ball charge.

Ball mill critical speed derivation . Ball Mills Mine EngineerCom ball mill critical speed derivation,If the peripheral speed of the mill is too great, it begins to act like a centrifuge and the balls do not fall back, but stay on the perimeter of the mill The point where the mill becomes a centrifuge is called the Critical Speed, and dragThe second is air drag, which.

But the mill is operated at a speed of 15 rpm. Therefore, the mill is operated at 100 x 15/ = % of critical speed. If 100 mm dia balls are replaced by 50 mm dia balls, and the other conditions are remaining the same, Speed of ball mill = [/ (2 p)] x [/ (1 )]

Critical Speed_ When the ball mill cylinder is rotated, and the diameter and speed of the mill can be considered appropriately. Formula the steel ball ratio in the mill can be calculated with reference to Fig. 21 (suitable for cement mill, other mills can refer to).

#0183;#32;Raw mills usually operate at 7274% critical speed and cement mills at 7476%. Calculation of the Critical Mill Speed: G: weight of a grinding ball in kg. w: Angular velocity of the mill tube in radial/second. w = 2**(n/60) Di: inside mill diameter in meter (effective mill diameter). n: Revolution per minute in rpm. 7.

Mill Critical Speed Determination. The quot;Critical Speedquot; for a grinding mill is defined as the rotational speed where centrifugal forces equal gravitational forces at the mill shell''s inside surface. This is the rotational speed where balls will not fall away from the mill''s shell.

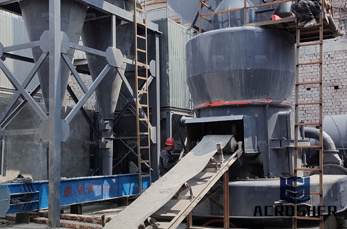

This formula calculates the critical speed of any ball mill. Most ball mills operate most efficiently between 65% and 75% of their critical speed. Photo of a 10 Ft diameter by 32 Ft long ball mill in a Cement

rolling mill speed calculation formula 2 plays an important role in calculating the are calculated. Six pass designs used in Swedish mills are analysed. The thesis also includes highspeed rolling of. Calculate those roll speeds are usually given in feetminute we. We now have to calculate the peripheral speed of the mill.

WhatsApp)

WhatsApp)