(PDF) SIZE REDUCTION BY GRINDING METHODS

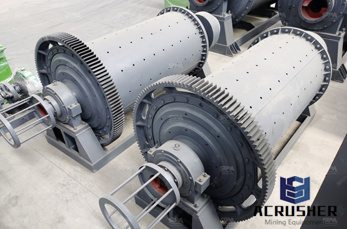

Ball mills are used primary for single stage f ine grinding, regrinding, and as the second s tage in two stage grinding circuits. According to the need of customers, ball mill can be either wet or dry

WhatsApp)

WhatsApp)

Ball mills are used primary for single stage f ine grinding, regrinding, and as the second s tage in two stage grinding circuits. According to the need of customers, ball mill can be either wet or dry

The larger particles from this mill are returned to the mill for more grinding. The finer particles receive more grinding in a ball mill, and are size classified to give a final product of 80% lt; microns. See more detail on grinding and sizing. 5. Leaching and adsorption

Please find below two calculators for sizing mills using the Bond and Rowland methods: Ball mill sizing: Calculator for ball mill(s) in a single stage circuit. Rod ball mill sizing: Calculator for rod mill(s) as first stage of the circuit and ball mill(s) as second stage of the circuit.

how to differentiate primary ball mill and secondary ball mill. Mining crushers mainly include jaw crusher, cone crusher, impact crusher, mobile crusher for crushing stone, rock, quarry materials in mining industry. Mill (grinding) Wikipedia, the free encyclopedia. Ball mills normally operate with an approximate ball charge of 30%.

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium. Different materials are used as media, including ceramic balls, flint pebbles, and stainless steel balls.

In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do. Often, the ball used in ball mills is oversize just in case. Well, this safety factor can cost you much in recovery and/or mill liner wear and

10 tonnes per hour mobile ball mill. The new primary crusher can handle up to 1200 tonnes per hour, although will generally operate at MRM''s Mal Stevens with the new ball mill, which is twice the sizeball mill cost for 100 ton cement production plant. 36 x 1000 mining conveyors overland pricing. hargal stone crusher plant 150 tph.

Sizing a Ball Mill Mining engineering EngTips. Nov 5, 2007 Our company is looking to replace our current ball mill and I was just wondering if anyone had some insight (websites, books, personal... Read more. Manufacturing Union Process. Table 1.

Mill sizing method The Mining Grinding Technology Website. The mill sizing page: Please find below two calculators for sizing mills using the Bond and Rowland methods. Design of ball mill sizing has strict standards. is the professional ball mill supplier and manufacture.

Mining and Mineral Engineering (ABSTRACT) In previous studies, the analysis of ball mill #176; operating parameters and their effects on breakage phenomena has been limited to homogeneous materials. Though these #223; studies have proven to be an asset in predictions of product size distributions and mill scaleup, they have not

The image below is just an example. Access to calculators is reserved for subscribers.

mining equiptment jaw rock crusher small used,cost ore beneficiation plants in saudi arabia,jaw crusher pe 400 dec ABOUT US Since its establishment in 1987, we have focused on the Ramp;D and manufacturing of largescale equipment required for national infrastructure construction projects such as mining, construction, and energy.

Ball Mills, Grinding Media, Primary, Secondary, Comminution, Size Description and images of ball grinding mills used in primary and secondary reduction of materials for the mining / mineral processing industry. Read more

A) Total Apparent Volumetric Charge Filling including balls and excess slurry on top of the ball charge, plus the interstitial voids in between the balls expressed as a percentage of the net internal mill volume (inside liners). B) Overflow Discharge Mills operating at low ball fillings slurry may accumulate on top of the ball

WhatsApp)

WhatsApp)