Quebec Gold Mines: 2019 Actual And 2020 Forecast

Aug 21, 2020#0183;#32;The Troilus Gold Project is a pastproducing gold mine that produced 2 million ounces of gold and 70,000 tonnes of copper since production began

WhatsApp)

WhatsApp)

Aug 21, 2020#0183;#32;The Troilus Gold Project is a pastproducing gold mine that produced 2 million ounces of gold and 70,000 tonnes of copper since production began

Sep 23, 2019#0183;#32;New technology that delivers commercialscale, cyanidefree gold processing has been released by Clean Mining. The company works to transform gold production worldwide in an environmentally responsible manner. The innovative, costeffective process replaces cyanide with a safer, less hazardous chemical reagent, thiosulphate.

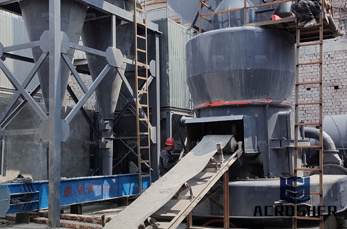

Gold Mining And Processing Flow Chart The gold mining and processing flow chart in general by the jaw crusher, ball mill, classifier, flotation machine, thickener and drying machines and other major equipment composition, these devices need to line the mineral processing production with feeder conveyor, hoist, etc. complete.

The Wohlwill process increases purity to about percent by electrolysis. In this process, a casting of impure gold is lowered into an electrolyte solution of hydrochloric acid and gold chloride. Under the influence of an electric current, the casting functions as a

Jan 23, 2012#0183;#32;In modern times though, mining for gold is a much more intensive, yet sophisticated process. Most surface, or alluvial gold has been found, which is why gold is mainly mined from the earth today. Its largely a matter of technology and requires much expertise and elaborate equipment. Mining for gold today can essentially be broken down into 9

The company boasts mining assets in both its home country of Canada and in Australia, and it has ambitious production targets to generate between 950,000 and 1 million ounces of gold annually from

The goldrich eluate is fed into an electrowinning circuit where gold and other metals are plated onto cathodes of steel wool. The loaded steel wool is pretreated by calcination before mixing with uxes and melting. Finally, the melt is poured into a cascade of molds where gold

May 23, 2017#0183;#32;Much of the gold found on earth was mined and prospected many years ago. The process of finding and mining new sources of gold is a challenging endeavor. Our mining techniques have grown more sophisticated in modern times, but we can still only mine what is available. And the more scarce gold becomes, the more likely we are to see prices increase.

The Basics of Gold Mining and Processing. Placer deposits, such as streambeds where people can pan for gold, are not the typical locations used by commercial gold mining companies. The process begins when geologists take ore samples to determine the

A slurry of ground ore, water and a weak cyanide solution is fed into large steel leach tanks where the gold and silver are dissolved. Following this leaching process the slurry passes through six adsorption tanks containing carbon granules which adsorb the gold and silver. This process removes 93% of the gold and 70% of the silver.

This is a list of countries by gold production in 2018.. Until 2006 South Africa was the world''s largest gold producer. In 2007 increasing production from other countries and declining production from South Africa meant that China became the largest producer, although no country has approached the scale of South Africa''s period of peak production during the late 1960s and early 1970s.

This 15minute Newmont documentary outlines the process of how gold is mined and how the process has changed over the past 150 years. Visit our website to le...

Bronze Age gold objects are plentiful, especially in Ireland and Spain, and there are several well known possible sources. Romans used hydraulic mining methods, such as hushing and ground sluicing on a large scale to extract gold from extensive alluvial (loose sediment) deposits, such as those at Las was under the control of the state but the mines may have been leased to

Goldloaded carbon and slurry are lifted by carbon pump or airlifter to separation sieve (the most popular sieve is liner vibrating sieve). Goldloaded carbon and slurry are separated by water on the sieve surface, and then goldloaded carbon is sent to carbon storage tank and the

Gold mining was first carried out in alluvial areas Processing system is also very simple to do that is by panning using a tray which then developed with gold mining wave table and followed by gravity separation method using the amalgamation process with the capture of mercury

gold at 1300#176;C, with fluxes of silica, feldspar, and borax, to remove impurities. Complete separation occurs within hours, at which point the slag is poured off and the molten gold is poured into anode casts and cooled. The anodes are approximately 99% pure and are submerged with % pure rolled gold cathodes in an electrolytic solution

Gold Mining | Gold Production | World Gold Council

Gold mining in the People''s Republic of China has made that country the world''s largest gold producer by far with tonnes in 2016. For the year 2007, gold output rose 12% from 2006 to 276 tonnes (9,700,000 oz; 304 short tons) to become the world''s largest for the first timeovertaking South Africa, which produced 272 tonnes (9,600,000 oz; 300 short tons).

911MPE has small gold mining equipment for sale and more specifically mineral processing equipment is best used in small scale extractive metallurgy operations operated by small miners or hobbyist prospectors and mining fanatics. 911MPE offers gold mining equipment as well as processing equipment applicable to most any base metals: copper, lead, zinc, nickel, tin, tungsten and

Around 19% of production comes from Africa and 14% from the CIS region. See our interactive gold mining map for gold production per country in 2019. Overall levels of mine production have grown significantly over the last decade, although substantial new discoveries are increasingly rare and production levels are increasingly constrained.

The 8 Stages of the Gold Mining Cycle. Gold mining is uncertain, expensive, competitive, and highly intensive. In 2014, the Minerals Council of Australia broke down the typical mining cycle into eight stages. The most expensive stages are 4, 5, and 6. Generative Stage; The process of discovering mineable gold deposits.

The Miller process uses gaseous chlorine to extract impurities when gold is at melting point; impurities separate into a layer on the surface of the molten purified gold. The Miller process is rapid and simple, but it produces gold of only about percent purity. The Wohlwill process increases purity to about percent by electrolysis.

Sep 23, 2020#0183;#32;Canadas gold mine production is estimated to grow by a compound annual growth rate of percent from 2019 to 2023 to reach million ounces. 6. Peru tonnes. Gold output fell for a fourth consecutive year in Peru largely due to crackdowns on illegal mining operations in the La Pampa region and lower grades at existing projects.

WhatsApp)

WhatsApp)