Lecture05 Pulverized Coal Firing PPE YouTube

Explained about working of Pulverized Coal Firing, Classifications....

WhatsApp)

WhatsApp)

Explained about working of Pulverized Coal Firing, Classifications....

Pulverised coal firing is done by two systems: i) Unit system or Direct System. ii) Bin or Central system . Unit System: In this system, the raw coal from the coal bunker drops on to the feeder. Hot air is

1. (1)Complete conversion from coalfiring to natural gas firing 2. Utilizing full load gas firing capabilities integrated into the existing (2)coalfired system (cofiring) 3. Decommissioning of the coalfired facility 4. Natural gas for preheated coal

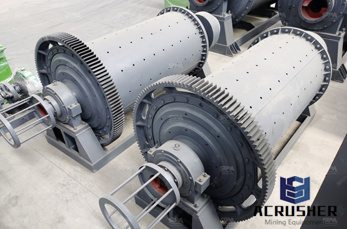

Pulverizedcoal firing is especially suitable for very large boilers and cement kilns. A wide range of coals can be burnt, but coal preparation and gas cleaning are major cost items. 70% lt; 75 m is required for bituminous coals, 80% for anthracite. Coal dried with air at 250350#176;C for milling in low, medium or highspeed mills. Main milling costs are power and replacement of worn parts.

Pulverized coal [PC] firing can pose unique challenges such as poor grinding performance, high carbon in ash, slagging problems and excessively high furnace heat fluxes due to combustion related issues.

Nov 12, 2019#0183;#32;Ammonia cofiring pulverized coal () boiler 6 Task : Optimization of the combustion system for the NOx reduction. Feasibility study to introduce ammonia into the existing power plant 2017FY : Cofiring test using 10MW thermal test furnace

For more than two decades, ALSTOM Power Inc. (ALSTOM) has developed a range of low cost, infurnace technologies for NOx emissions control for the domestic pulverized coal fired boiler

Oct 27, 2020#0183;#32;In the pulverized fuel firing system, we make the coal in fine particles with the help of grinding mills. We refer the process of making the fuel powder as pulverization. This pulverized coal gets sprayed in the combustion chamber with a blow of hot air.

The potential for fires and explosions inherent in air and pulverized coal mixtures has been studied for over 60 years. Design and operating practices have evolved to a state that allows the safe, practicable utilization of airconveyed coal pulverizing systems for direct firing

Oct 27, 2020#0183;#32;On the other hand, the pulverized fuel firing system is universally accepted method of boiler firing in the modern age, mainly because it increases the thermal efficiency of solid fuel to a great extent. In the pulverized fuel firing system, we make the coal

Jan 01, 1982#0183;#32;Pulverizedcoal firing is especially suitable for very large boilers and cement kilns. A wide range of coals can be burnt, but coal preparation and gas cleaning are major cost items. 70% lt; 75 m is required for bituminous coals, 80% for anthracite. Coal dried with air at 250350#176;C for milling in low, medium or highspeed mills. Main milling costs are power and replacement of worn parts.

Pulverised Coal an overview | ScienceDirect Topics

An airpurged burner for the firing of pulverized solvent refined coal is constructed and operated such that the solvent refined coal can be fired without the coking thereof on the burner components. The airpurged burner is designed for the firing of pulverized solvent refined coal in a tangentially fired boiler.

domestic pulverized coal firing. Pulverised Coal an overview ScienceDirect Topics. Pulverizedcoal firing is especially suitable for very large boilers and cement kilns A wide range of coals can be burnt, but coal preparation and gas cleaning are major cost items 70% 75 m is required for bituminous coals,

coalfired (PCfired) boilers, the fuel is pulverized to the consistency of talcum powder (, at least 70 percent of the particles will pass through a 200mesh sieve) and pneumatically injected through the

Jan 01, 1982#0183;#32; Pulverizedcoal firing. The essential feature of pulverizedcoal firing is that throughout the combustion the fuel is suspended as a cloud of small particles in the combustion air.

An airpurged burner for the firing of pulverized solvent refined coal is constructed and operated such that the solvent refined coal can be fired without the coking thereof on the burner components. The air

A pulverized coalfired boiler is an industrial or utility boiler that generates thermal energy by burning pulverized coal that is blown into the firebox. The basic idea of a firing system using pulverised fuel is to use the whole volume of the furnace for the combustion of solid fuels. Coal is ground to the size of a fine grain, mixed with air and burned in the flue gas flow. Biomass and other materials can also be

Apr 12, 2018#0183;#32;The video makes it clear that how ammonia is supplied inside the pulverized coal flow path is a key determinant of whether there is an increase [of] NOx and N2O in the exhaust gas. In December the Nikkei Sangyo Shimbun reported that IHI was interested in ammoniacoal technology and also intended to achieve a 20% cofiring rate.

Enhanced Combustion Low NOx Pulverized Coal Burner PUBLIC ABSTRACT For more than two decades, ALSTOM Power Inc. (ALSTOM) has developed a range of low cost, infurnace technologies for NOx emissions control for the domestic pulverized coal fired boiler market. This includes ALSTOMs internally developed TFS 2000TM firing system,

Nov 12, 2019#0183;#32;Ammonia cofiring pulverized coal () boiler 6 Task : Optimization of the combustion system for the NOx reduction. Feasibility study to introduce ammonia into the existing power plant 2017FY : Cofiring

Pulverized coal fired boilers the total losses account to about 12 to 14 %. Roughly 50% of the losses can be tuned to the optimum and the other 50 % is governed by fuel properties like hydrogen in fuel,

Pulverizedcoal firing is especially suitable for very large boilers and cement kilns. A wide range of coals can be burnt, but coal preparation and gas cleaning are major cost items. 70% lt; 75 m is required for

WhatsApp)

WhatsApp)