NEW LOCOMOTIVES Mining, Construction Equipment

McDowell Heavy Equipment Sudbury, Ontario new and used construction mining heavy equipment amp; parts for surface and underground delivered worldwide.

WhatsApp)

WhatsApp)

McDowell Heavy Equipment Sudbury, Ontario new and used construction mining heavy equipment amp; parts for surface and underground delivered worldwide.

Keywords: Ball mills, grinding circuit, process control. I. Introduction Grinding in ball mills is an important technological process applied to reduce the size of particles which may have different nature and a wide diversity of physical, mechanical and chemical characteristics. Typical examples are the various ores, minerals, limestone, etc.

Planetary ball mills 9 . Vibration Mills 10 . Mixer Mill MM 400 11 Feed material: hard, mediumhard, soft, brittle, elastic, fibrous Material feed size: 8 mm Final fineness: ~ 5 #181;m Setting of vibrational frequency: digital, 3 30 Hz (180 1800 min1)

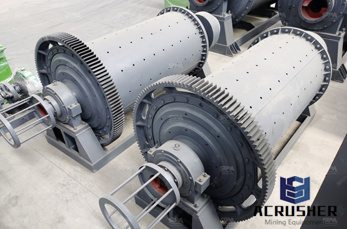

The ball mill machines mainly include: raw mill, coal ball mill, ore ball mill, small ball mill, wet ball mill, ceramic ball mill, overflow ball mill, as well as vertical ball mill, rod mill and automatic/semiautomatic mill and other industrial milling equipment. These industrial ball mills are widely used in cement manufacturing, mining

Boliden Allis () 24''x9'' 3,000 HP SAG Mill Available Aug 26; King Sells Unused HP800 Cone Crusher for Project in Canada Aug 26; King Sells Mobile Skidded 4x5 Ball Mill Jul 21

Metallurgical ContentBall Mill Capacity VS Rod Mill CapacityWorking Principle amp; OperationRod Mill Capacity TableBall VS Rod Mill ConversionTypes of Mill DischargeBall Mill Trunnion and Mill Grate DischargePeripheral Grinding Mill DischargeLoad Capacity of Trunnion BearingsBall Mill amp; Rod Mill LinersGrinding Mill GearsGrinding Mill DrivesBall Mill Grinding CircuitBall Mill SpecificationsAll

Nano Ball Milling 1. BALL MILLING METHOD By Aravind N. B 2. Nano materials can be defined as those materials which have structured components with size less than 100nm at least in one dimension. Nanotechnology is an advanced technology, which deals with the synthesis of nanoparticles, processing of the nano materials and their applications.

Ball Mill Grinding,Manufacturers,Ball Mill Price,Working Ball Mill Grinder Manufacturers . Ball Mill Grinding is typically mill grinding plant used for small and large quarry mineral grinding /

, with over a century of experience, designs and manufactures the most comprehensive line of grinding mills and entire grinding systems for mining companies around the world. The comprehensive offering provides reliable and energy efficient technology and solutions across wet, dry, horizontal, and vertical grinding operations.

Inventory ID: 6CHM01. 3 Units UNUSED FL 26 x 43'' Dual Pinion Ball Mill with 2 ABB 9,000 kW (12,069 HP) Motors w/ ABB VFD for Total Power of 18,000 kW (24,138 HP)

Mining Ball Mill. Durable Horizontal Mining Ball Mill For Mineral Ore Beneficiation Plant; Dry Type Heavy Duty Industrial Mining Ball Mill Machine / Gold Ball Mill #187; Learn More. Description : file type ppt ball mill 16 Jan 2014 handbook operational file type ppt ball mill. is a maintenance of heavy equipment filetype ppt 19 Jun

https:// Learn about Ball Mill Critical Speed and its effect on inner charge movements. The effect of Ball Mill RPM spe...

A Ball Mill Critical Speed (actually ball, rod, AG or SAG) is the speed at which the centrifugal forces equal gravitational forces at the mill shells inside surface and no balls will fall from its position onto the shell. The imagery below helps explain what goes on inside a mill as speed varies. Use our online formula The mill speed is typically defined as the percent of the Theoretical

Ball Mill Lecture Ppt Mining Quarry Plant. Ball mill ppt presentation page 2 of results for the term ball mill ppt powerpoint templates presentations lecture notes warping millppt ppt powerpoint templates presentations free ppt templates presentations lecture notes for view download and edit high stresses results from a crushing action such as

Ball Mill Drives Process Advantages Mining Congress. Leandro Bomvisinho, M. Sc., Sales Manager Gearless Mill Drives As a result of today''s requirements for maximizing grinding throughput, larger ball mills. for slowly rotating the mill to perform a visual inspection or grinding out the mill

Optimization of mill performance by using online ball and pulp measurements by B. Clermont* and B. de Haas* Synopsis Ball mills are usually the largest consumers of energy within a mineral concentrator. Comminution is responsible for 50% of the total mineral processing cost. In todays global markets, expanding mining groups are trying

DEFINITON: A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering etc. 6. PRINCIPLE: A ball mill works on the principle of impact and attrition. size reduction is done by impact as the balls drop from near the top of the shell.

Ball mill consist of a hollow cylindrical shell rotating about its axis. Axis of the shell horizontal or at small angle to the horizontal It is partially filled with balls made up of Steel,Stainless steel or rubber Inner surface of the shell is lined with abrasion resistant materials such as Manganese,Steel or rubber Length of the mill is approximately equal to its diameter Balls occupy about

offers 175 ball milling ppt ball mill products. About 2% of these are Mine Mill, 13% are Grinding Equipment. A wide variety of ball milling ppt ball mill options are available to you, such as condition, local service location, and applicable industries.

WhatsApp)

WhatsApp)