(PDF) Modelling and design of rotary dryers

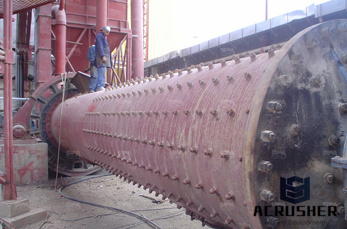

Sep 01, 1982#0183;#32;The drying takes place in rotary dryers, which consist of a cylindrical shell rotated upon bearings and usually slightly inclined to the horizontal.

WhatsApp)

WhatsApp)

Sep 01, 1982#0183;#32;The drying takes place in rotary dryers, which consist of a cylindrical shell rotated upon bearings and usually slightly inclined to the horizontal.

Jan 16, 2019#0183;#32;Rotary dryers, called the workhorse of chemical dryers, belong to the most widely used class of continuous dryers in process industries. These dryers are suitable for relatively freeflowing, nonsticky and granular materials; for example, almost all types of crystals after crystallization and washing. Typical applications of rotary dryers are in drying o table salt, sodium sulphate

PROCESS DESIGN OF DRYERS (PROJECT STANDARDS AND SPECIFICATIONS) Page 2 of 48 Rev: 01 April 2011 SCOPE This Project Standards and Specifications is intended to cover minimum requirements for process design of dryers used in oil, gas, and petrochemical process plants. Although, as a common practice, dryers are seldom designed by the users, but

Rotary Drum Dryer Working Principle VideoCynthia Tel: Skype:woodpelletmachine19 Email:machine19rotexm...

the process, the clay has a moisture content of 10 to 15 percent. For certain applications, the clay is dried in mechanical dryers to reduce the moisture content of the material to 7 percent or less. Typically, rotary and vibrating grate dryers fired with natural gas or fuel oil are used for drying fire clay.

Rotary dryer machine has a large processing capacity, less fuel consumption, and low drying cost. The drum dryer machine adopts the structure of adjustable center tugboat, which is well matched with the rolling ring and greatly reduces wear and power consumption.; The rice husk dryer machine is specially designed to block wheel structure, greatly reduce the horizontal thrust caused by the tilt

Description Rotary Dryer can be used for drying materials with certain humidity or granularity, widely used in building materials, metallurgy, chemical industry, cement industry drying slag limestone, sludge, slag, clay and other materials. The rotary drum dryer is mainly composed of rotary body, lifting plate, transmission device, supporting device and sealing ring and other parts.

If you are having a process issue, Industrial Kiln amp; Dryer has a solution. Our trusted partner, Optimus Process Solutions (OPS), has years of process knowledge and understands the science behind the can engineer and design a custom flighting system for your process no matter the brand or type of rotary drying equipment.

Nov 26, 2001#0183;#32;In direct heat rotary dryers, a hot gas flowing through the dryer provides the heat required for the vaporization of the water. To promote gassolid contact, most direct heat dryers have flights, placed parallel along the length of the shell, which lift solids and make them rain across the section of the dryer Fig. 1 ).

Brief introduction of clay dryer clay dryer is specially designed to dry materials with high viscosity like clay, gypsum and other clay rotary drum dryerwhich is produced based on germany advanced clay drying technology and has reasonable design, stable functioning, simple operation, wear resistance and durability, higher thermal efficiency and better drying effect the.

clay ore rotary Dryer Rotary Kiln CrusherJaw crusherSand makerBall millDryer clay rotary dryer design Rotary Dryer Manufacturer Get Price And Support Online Clay DryerClay Rotary DryerClay Drying MachineDryer Clay Dryer Clay dryer is specially designed to dry materials with high viscosity like clay gypsum and other materials.

Design Parameters Influenced by Heat Transfer. The unique heat transfer properties of a material can have a variety of effects on the overall design of a rotary dryer. Common design parameters that are influenced by heat transfer properties include: Air Flow Configuration. Air flow configuration can be cocurrent or counter current.

Rotary Dryers are one of the widely used Dryer in process industry. Especially in fertilizer and minerals industry for drying products such as coal, clay, gypsum, kaolin, limestone, mineral sand, potash, silica sand etc. Rotary Dryers from SAKA provide controlled, uniform and efficient drying to help you achieve desired product quality.

Design Issues: Mechanical Dryers 1. Introduction: There are three generic forms of mechanical dryer commonly found in use today. The vertical dryer, the horizontal dryer and the silo or stationarybed dryer. These are batch dryers which naturally fit the batch pattern dictated by coffee processing, following, as it does, daily (or less frequent)

flow for ball clay processing. Indirect rotary or vibrating grate dryers are used to dry ball clay. Combustion gases from the firebox pass through an airtoair heat exchanger to heat the drying air to a temperature of approximately 300#176;C (570#176;F). The clay is dried to a moisture content of 8 to 10 percent. Following

These sand rotary dryer design are sturdy and perform optimally saving energy bills. MENU MENU English High Efficiency Rotary Dryer Mineral Sand/Wet Clay Rotary Dryer Powder Drying Biomass Rotary Dryer Design. US / Set. Sets (Min Order) Henan Hongke Heavy Machinery Co., Ltd.

Rotary dryers for particulate solids commonly use flights along the length of the shell to lift solids and make them rain across the dryer section. These flights are critical to dryer performance. Previous models for the prediction of the solids holdup in rotary drums have assumed that the angle of the solids level in a flight is independent of

ROTARY LIME KILNS Slides 1 and 2 are the title and outline for the presentation. Slide 3, below, shows a schematic of the exterior of a modern rotary limereburning kiln. Slide 4 shows a schematic of the interior features of a limereburning kiln. Rotary lime kilns are large steel tubes that are lined on the inside with refractory bricks.

Metallurgical ContentSizing a Rotary Dryer using a Capacity TableRotary Dryer Capacity TableROTARY DRYERS, DirectHeat DesignROTARY DRYERS, IndirectHeat DesignROTARY DRYERS, Tedrow Steam DesignRotary Dryer Direct Heat and Indirect Heat Type Capacity and Sizing Table For evaporating moisture from concentrates or other products from plant operations, Rotary Dryers are

WhatsApp)

WhatsApp)