Analysis of ball mill grinding operation using mill power

Analysis of ball mill grinding operation using mill power specific kinetic parameters. A twostage ball milling circuit for the grinding of molybdenum ore was investigated based upon the

WhatsApp)

WhatsApp)

Analysis of ball mill grinding operation using mill power specific kinetic parameters. A twostage ball milling circuit for the grinding of molybdenum ore was investigated based upon the

steel grinding ballhe steel grinding ball is a kind of the grinding medium applied in the cylindrical ball grinding mill for grinding the oret is widely applied into the grinding industry such as the iron ore and nonferrous metal dressing plant, cement plant, thermal power plant, refractory material factory, iron and steel plant.

influences the grinding efficiency. In iron ore, for instance, a variation of 2 to 3% solid content in the slurry could lead to a difference up to 10% on the energy (kWh/T) for a similar grind. Optimization of mill performance by using online ball and pulp measurements J o u r n a l P a p e r

Iron Ore Grinding Ball Mill Manufacturers, Factory, Suppliers From China, sincerity and strength,always keep approved good quanlity,welcome to our factoty for visit and instruction and business. Mobile Phone Benito Hwen: + Call Us + Email benitohwen .

mill is the energy consumption. The power supplied to the mill is used primarily to lift the load (medium and charge). Additional power is required to keep the mill rotating. Power drawn by ball, semiautogenous and autogenous mills A simplified picture of the mill load is shown in Figure Ad this can be used to establish the essential

Ball mills. The ball mill is a tumbling mill that uses steel balls as the grinding media. The length of the cylindrical shell is usually times the shell diameter ( Figure ). The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 2040

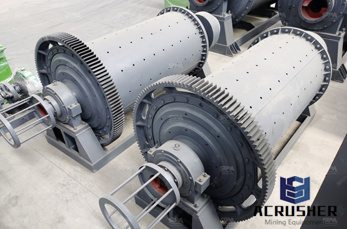

Photo about Ball mill for grinding iron ore. Image of mechanical, energy, engineering

Dry type ball mill is a grid ball mill of horizontal rotating device with outer gear drive device, two hoppers. Materials evenly spirally enter into the first hopper through hollow shaft, the warehouse has stepped lining board or corrugated liner board and different sizes of steel balls, the centrifugal force produced by cylinder rotation brings the steel balls to a certain height, then the falling balls pound and

ball mill for iron ore grinding in malaysia quarry mining. ball mill manufacture and for sale. especially for malaysia iron ore grinding, you can choose our ball mills. for almost 30 years, ball mills

Vertical roller mills The new leader in grinding technology. Oct, sulphide coppergold ores are usually sorted by flotation the standard comminution process to grind the ore to flotation fineness, mostly consists of coarse crushing followed by sag milling or wet ball mill circuits, or alternatively multiple stage crushing followed by rod and ball milling

7 #0183;#32;Manufacturer of Ball Mill Batch Ball Mill, Rod Ball Mill, Iron Ore Grinding Ball

The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory material, fertilizer, glass ceramics, etc., as well as for ore dressing of ferrous and nonferrous metals. The ball mill can grind ores and other materials, wet or dry.

Metallurgical ContentBall Mill Capacity VS Rod Mill CapacityWorking Principle amp; OperationRod Mill Capacity TableBall VS Rod Mill ConversionTypes of Mill DischargeBall Mill Trunnion and Mill Grate DischargePeripheral Grinding Mill DischargeLoad Capacity of Trunnion BearingsBall Mill amp; Rod Mill LinersGrinding Mill GearsGrinding Mill DrivesBall Mill Grinding CircuitBall Mill SpecificationsAll

This is particularly true for some of the secondary grinding (primary ball mills) of magnetic iron ores. In magnetic iron ore grinding, the silica levels are continually being decreased from crushing to rod milling to ball milling by intermediate concentration steps. Subsequently, the wear environment becomes progressively less abrasive.

US 9,900. Our Laboratory Grinding Mill comes standard with a 1 HP motor and optional variable speed drive ranging from 1 to 100 RPM. This Grinding Mill is fully enclosed with sound dampening material for a quiet workplace. The sheet metal steel fabrication

offers 3,416 ball mill for grind iron ore products. About 59% of these are Mine Mill, 0% are Grinding Equipment. A wide variety of ball mill for grind iron ore options are available to you, such as condition, local service location, and applicable industries.

Iron Ore Grinding Machinesball Mill For Iron Ore. Ball mill for iron ore grinding plant . Ball mill is one of the most old flour mill equipments which is one of the earliest flour mill that was applied in iron ore grinding field.

Power: Capacity: Effective volume: Speed: Steel ball filling: Iron ore: 4500Kw: 320t/h: 191m 3: /min: 335t 18: 90% HENGIN can provide CITIC, SINOMA, NHI and other brand Grinding Mill,Ball mill, SAG mill,AG mill,Rod mill and spare parts for mine customers around world. Process 1Gringding Mill Design 2Gringding Mill Manufacturing

The IsaMillTM is an energyefficient mineral industry grinding mill that was jointly the various minerals in an ore, because the iron from the grinding medium can affect the. to allow coarse oversize product to be returned to the mill for a second pass).. For comparison, the power intensity of a ball mill is about 20 kW/m3. Get Price

Ore Milling Equipment,Iron ore mining equipment,Iron ore . iron ore ball mill for sale Iron Ore Ball mills are used primary for single stage fine grinding, regrinding, and as the second stage in two stage grinding circuits According to the will need of customers,Iron Ore ball mill could be either wet or dry designs These mills are sized from two t/h to 30 TPH for wet grinding and from 05 t/h

WhatsApp)

WhatsApp)