Coal Mills in thermal power plant | Mill (Grinding

PRINCIPLES OF GRINDING Raw Coal is fed into the Mill for Grinding. Grinding takes place by Impact and attrition. MILL DETAILS. Design coal capacity Tons/Hr Ball charged 90 Tons Speed 15 to

WhatsApp)

WhatsApp)

PRINCIPLES OF GRINDING Raw Coal is fed into the Mill for Grinding. Grinding takes place by Impact and attrition. MILL DETAILS. Design coal capacity Tons/Hr Ball charged 90 Tons Speed 15 to

Explain about functions of thermal power plant pa fan PA Fan is primary air fan which is used in power plant to push the coal from mill to furnace and to maintain the powdered coal

For nearly 100 yearsever since pulverized coal combustion was adapted for power generationGE has been a leader in coal mill technology for the power industry. That leadership continues today with the worlds largest fleet of installed power milling equipment. Licenses for our milling technology can be found in all coalpowered regions of the world.

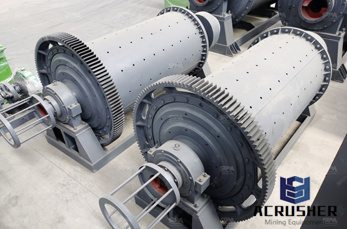

Coal Mill in Power Plant, Working Principle of Ball Mill. Ball Mill Popular Coal Mill in Powder Plant. Because coal is the main purpose of fuel for power plants, and so will usually choose Ball Mill as a coal Mill in powder plant, Ball Mill, Ball Mill, the performance characteristics of Ball Mill for the edge of the transmission, by the motor through reducer...

If there are surplus/backup coal mills available, they can be modified to biomass, which reduces the investment costs, but then the backup capacity is, of course, lost. The separate milling option is in use in Essent 600 MW e Amer9 power plant located in the Netherlands. The plant cofires pelletised biomass on 27% energy share.

Power Plant coal Mill Manufacturer. SBM is a mill (Coal Mill) started largescale mining equipment manufacturing enterprises, since 1987, has been committed Powder Making Method of research and innovation, development, and manufacturing of the Raymond mill (Coal Mill), high pressure hanging roller mill, vertical mill, overpressure trapezium

Jun 21, 2018#0183;#32;This is the coal mill of thermal power this is section coal is feed by is mainly ball type mill,coal is pulverized by the ball like

Southwestern Corporation designs and manufactures coal mill / pulverizer products for CE, Babcock amp; Wilcox, Foster Wheeler, and Loesche pulverizers. cable sweep, cable mill sweep, power plant, utility,

Nov 17, 2012#183; 3. pulverizer/mill system One of the critical power plant components that is relied upon to convert the energy stored in coal into electricity is the coal pulverizer or mill. The coal flow is controlled by the feeder, allowing coal to flow into the pulverizer mill. The pulverized coal

The vertical spindle mill is a medium speed pulverizer and maintains a considerable amount of fuel in the mill system when operating. Coal collects on the grinding table, in the classifier, in the pyrite collection sec tion below the grinding table, and at the fan exit for exhauster systems. These are the prime locations of fires.

The Mill Creek Generation Station is LGamp;Es largest coalfired power plant, with a generating capacity of 1,465 megawatts. Mill Creek sits on 544 acres in southwest Jefferson County, Ky. The late 1960s and

May 27, 2020#0183;#32;Power companies have announced plans to close 13 coal plants this year, according to an Eamp;E News review of federal data and companies closure plans. Two others will be converted to

Jan 23, 2018#0183;#32;For coalfired power plants, the response time of the coal mills is critical for the overall reaction time to changing demand. Flexible operation or load following requires that the output of the plant can be made to vary in accordance with demand and in accordance with allowable ramp rates.

Coal mill pulverizer in thermal power plants

Nov 17, 2012#0183;#32; pulverizer/mill system One of the critical power plant components that is relied upon to convert the energy stored in coal into electricity is the coal pulverizer or mill. The coal flow is controlled by the feeder, allowing coal to flow into the pulverizer mill. The pulverized coal and air mixture is then transport to the boiler burner panels.

Coal Mill in Power Plant, Working Principle of Ball Mill. Ball Mill Popular Coal Mill in Powder Plant. Because coal is the main purpose of fuel for power plants, and so will usually choose Ball Mill as a coal Mill in powder plant, Ball Mill, Ball Mill, the performance characteristics of Ball Mill

Pulverizers (coal pulverizer) are used to pulverize pieces of coal into fine particles (100m) before placing into a boiler, to ensure efficient combustion.

Coal Mill Pulverizer In Thermal Power Plants. Nov 17, 2012 3. pulverizer mill system One of the critical power plant components that is relied upon to convert the energy stored in coal into electricity is the coal pulverizer or mill. The coal flow is controlled by the feeder, allowing coal to flow into the pulverizer mill. The pulverized coal

The vertical spindle mill is a medium speed pulverizer and maintains a considerable amount of fuel in the mill system when operating. Coal collects on the grinding table, in the classifier, in the pyrite collection

May 13, 2020#0183;#32;The coal can be transported from mines to the power plant by means of trucks, tippers, tractors etc., through road, but it is used only for small capacity power stations. The major advantage of this type is that the coal can be carried directly into the powerhouse up to the point of consumption. The pulverised coal from a mill

Dec 01, 2015#0183;#32;5. Mill power to ton of coal throughput. In general, when the mill draws more power per ton of fuel, it is an indication that finer coal is being produced. Source: Storm Technologies

Sep 17, 2017#0183;#32;In the starting of the plant, pulverized coal from mill machine supplied to the boiler furnace by PA fan. FD fan provides desire oxygen for proper burning. DM water is supplied by the Boiler feed

WhatsApp)

WhatsApp)