Workholding for Turning and Grinding Machine Tools

SMWAUTOBLOK is among the leading manufacturers worldwide of workholding for turning and grinding machine tools. AUTOBLOK Via Duca d''Aosta, 24

WhatsApp)

WhatsApp)

SMWAUTOBLOK is among the leading manufacturers worldwide of workholding for turning and grinding machine tools. AUTOBLOK Via Duca d''Aosta, 24

Home / Products / Machine Tools Workholding. Machine Tools Workholding The permanentelectro magnetic clamping for high precision grinding operations... More details... Radial Pole. The guarantee of the highest quality standards in turning and vertical grinding... More details...

As the only machine tool OEM provider offering turning, milling, grinding, workholding and custom manufacturing solutions, Hardinge is ideally positioned to provide you with an innovative, costeffective custom solutions that meets your needs. Learn More

In a grinding machine, there is an electric motor which supplies the motion power to the grinding wheel with the help of a belt and pulley.. So when we start the electric motor the motor rotates at a certain rpm ( RPM, it may change according to the types of grinding machine) with the help of vbelt and cone pulley the grinding wheel also starts rotating and we perform the operation.

Grinding machines have Grinding, or abrasive machining, once performed on conventional milling machines, lathes and shapers, are now performed on various types of grinding machines. Grinding machines have advanced in design, construction, rigidity and application far more in the last decade than any other standard machine tool in the manufacturing industry.

A workholding device used in grinding that holds the workpiece to a 90#176; vertical surface using clamps Angle plates are used to grind edg, A grinding machine component that controls motion of the table along the base ways The table handwheel controls back and forth table movement.. Know More

Grinding Machine provides 2 meter capacity., Hardinge Workholding The Hardinge Grinding Group introduces a new 2meter capacity, UltraGrind 2000 grinding machine manufactured by Jones amp; Shipman, a Kellenberger Company,

Workholding devices Almost any workholding device used on a milling machine or drill press can be used on surface grinders. However, the most common workholding device on surface grinders is a magnetic chuck. Cylindrical grinding Cylindrical grinding is the process of grinding

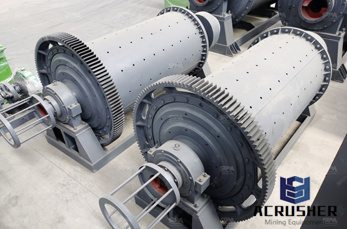

Types Of Workholding Devices On A Grinding Machine. We are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment, milling equipment, mineral processing equipment and building materials equipment.

Workholding made by Reishauer Highprecision grinding results demand an equally high precision in clamping Reishauer builds on its own comprehensive knowledge of the gear grinding process and on this basis, develops and manufactures customer specific clamping devices.

SMWAUTOBLOK is among the leading manufacturers worldwide of workholding for turning and grinding machine tools. SMWAUTOBLOK Telbrook . Unit 7 Wilford Industrial Est. Ruddington Lane Nottingham NG11 7EP

Cylindrical grinding (also called centertype grinding) is used to grind the cylindrical surfaces and shoulders of the workpiece. The workpiece is mounted on centers and rotated by a device known as a lathe dog or center driver. The abrasive wheel and the workpiece are

Workholding for Cylindrical Grinding Canadian Metalworking

Workholding Surface Grinding Machine Basic Motions; Workholding Surface Grinding Machine Basic Motions. Grinding machines have advanced in design construction rigidity and application far more in the last decade than any other standard machine tool in the manufacturing industry Grinding machines fall into five categories surface grinders

Hardinge Workholding. Hardinge Workholding is the leader in quality standard and custom collets. Over the years, we have expanded our collet and workholding options to satisfy a variety of applications and machine types. Learn More About Hardinge Products

Manufacturer of workholding chucks for grinding machines. Chucks are available with repeatability ranging from in. to in. More details. Magnetic Surface Grinding Chucks . Use magnetic workholding for drilling, milling, and boring . Magnetic chucks allow free access to machine on 5 sides.

WhatsApp)

WhatsApp)