Cement Bag Making Machine and Manufacturing Process

Hao Yu offer cement bag making machine with high technology and precise manufacturing process. For further about cement bag machine, welcome contact us.

WhatsApp)

WhatsApp)

Hao Yu offer cement bag making machine with high technology and precise manufacturing process. For further about cement bag machine, welcome contact us.

While the process of making cement uses a number of tools, the production of concrete requires only a concrete mixer. In the first stage of making cement, limestone and clay are crushed together to form a powder. This powder is then combined in a mixer before passing into a rotating heater which has constant heat applied at one end of the tube.

Concrete block is a primary building material. Many different raw materials go into a block making machine like a mixture of cement, gravel, water and sand.. Concrete Blocks Manufacturing Process Concrete block making machines manufacturing concrete blocks using the steps:

Sand Making Machine gt; Cement making simple process; Cement making simple process. We are here for your questions anytime 24/7, welcome your consultation. Get Price. Sand Making Machine : A special equipment for the production of construction sand and stone. As a manufacturer of sandmaking equipment for 40 years,

#0183;#32;Cement Manufacturing Process Phase IV: Kiln Phase. Kiln is a huge rotating furnace also called as the heart of cement making process. Here, raw material is heated up to 1450 C. This temperature begins a chemical reaction so called decarbonation. In this reaction material (like limestone) releases the carbon dioxide.

Explore the cement manufacturing process below. Cement Vs. Concrete . Cement is often confused with concrete. A common misconception is cement and concrete are interchangeable terms. In reality, cement is the glue that binds concrete together, like flour (cement) in a loaf of bread (concrete).

7/12/2020#0183;#32;The cement manufacturing process involves several key steps, including preparing the raw materials, grinding the materials together, heating the newly formed clinker in a kiln, and finishing the cement with fine of the main ingredients used to make cement include limestone, clay, shale, iron, and manufacturing techniques will use either wet or dry grinding, but

Dry Process Cement Production LineCement Making Machinery. This cement making machinery is equipped with high efficient vertical roller mill grinding system This system is used to prepare coal powder It saves electricity by about 110 kWht per unit compared with the traditional cement process flow which is composed of air swept ball mill dynamic coarse powder separator and high concentration air

Concrete block is a primary building material. Many different raw materials go into a block making machine like a mixture of cement, gravel, water and sand.. Concrete Blocks Manufacturing Process Concrete block making machines manufacturing concrete blocks using the steps:

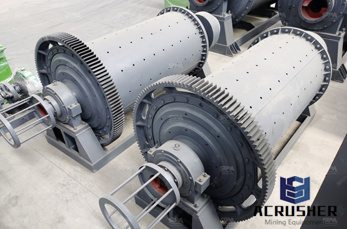

We have the process of cement making with ball mills,vertical grinding mill for cement process Grinding Mill Machine in Cement Production provides both large scale and small scale cement production plants for sale which are available with crusher plant cement grinding mill ball mill vertical roller mill rotary kiln etc Grinding occurs at the beginning and the end of the cement making process

Cement is so fine that 1 pound of cement contains 150 billion grains. The cement is now ready for transport to readymix concrete companies to be used in a variety of construction projects. Although the dry process is the most modern and popular way to manufacture cement, some kilns in the United States use a wet process.

1/4/2017#0183;#32;Cement Bag Making Machine Cement Bag Making Machine is one of the popular ingredients considered for making packaging components. Investing in raffia tape st...

Figure (5): The Wet process of cement (Masenan, 2008) Semidry process It example to dr y process and uses a L epol kiln : in the lepol kiln the pellets are dried and

A wide variety of cement making machine options are available to you, There are 15,990 suppliers who sells cement making machine on, mainly located in Asia. The top countries of suppliers are United States, China, and India, from which the percentage of cement making machine supply is 1%, 98%, and 1% respectively.

28/7/2020#0183;#32;Overall, there are six steps in the cementmaking process and concrete production is comparatively easier as it involves combining the right proportion of different ingredients. According to the first diagram, limestones and clays are two essential raw materials for the cementmaking process. They are put on a crushing machine and turned into

Accurate cement production also depends on belt scale systems to monitor output and inventory or regulate product loadout, as well as tramp metal detectors to protect equipment and keep the operation running smoothly. The Cement Manufacturing Process flow chart sums up where in the process each type of technology is making

WhatsApp)

WhatsApp)