Construction of Ball Mill/ Ball Mill Structure | Henan

Ball Mills an overview | ScienceDirect Topics

WhatsApp)

WhatsApp)

Ball Mills an overview | ScienceDirect Topics

Short Cylinder Ball Mill: The ball mill with the cylinder length (L) less than 2 times of the cylinder diameter, the ball mill with L 2D is short cylinder ball mill, which is usually of single bin structure, mainly used for rough grinding or primary grinding operation, and can realize the wide use of 23 ball mills

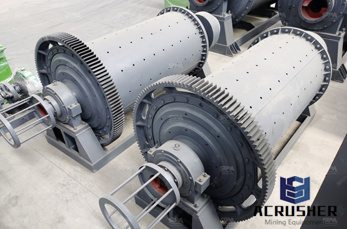

Ball MillFTM Machinery. Structure The ball mill is mainly composed of a feeder, a discharging port, a turning device, transmitting devices that include a reduction gear, a small transmitting gear, a motor, and the electric control The hollow shaft is made of cast steel so that the inner lining can be replaced.

Ball milling of graphite with appropriate stabilizers is another mode of exfoliation in liquid phase. 21 Graphite is ground under high sheer rates with millimetersized metal balls causing exfoliation to graphene (Fig. ), under wet or dry instance, this method can be employed to produce nearly 50 g of graphene in the absence of any oxidant. 22 Graphite (50 g) was ground in

Planetary Ball Mill Working Principle. Planetary Ball Mills consist of several cylindrical grinding jars (positioned on the sun wheel as shown on the figure) which are filled with loose grinding balls. Two superimposed rotational movements move the grinding jars: Like in a planetary system the grinding jar rotates on a orbit around the centre.

Ball mill introduction. Structurally, each ball mill consists of a horizontal cylindrical shell, provided with renewable wearing liners and a charge of grinding medium. The drum is supported so as to rotate on its axis on hollow trunnions attached to the end walls (attached figure 1 ball mill).

cone ball mill equipment|used cone coal mill manufacture china... highefficiency cone ball mill this machine changes the original ball mill machine... mill t zium mill stamp mill diatomaceous earth mill cone ball mill co powder mill coal mill cement mill bentonite mill bentonite grinding mill granite mill graphite mill powder grinding mill calcium carbonate mill grid ball mill...

A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it can be rotated along its longitudinal axis. The balls which could be of different diameter occupy 30 50 % of the mill volume and its size depends on the feed and mill size.

Planetary Ball Mills are used wherever the highest degree of fineness is addition to wellproven mixing and size reduction processes, these mills also meet all technical requirements for colloidal grinding and provide the energy input necessary for mechanical extremely high centrifugal forces of a planetary ball mill result in very high pulverization energy and

#0183;#32;Henan Bailing Machinery Co., Ltd. Offical website: Alibaba website: Product webpage:http...

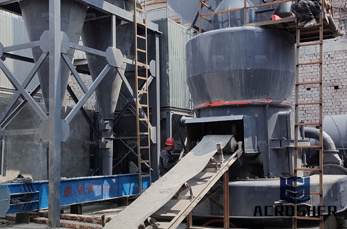

A VSI mill throws rock or ore particles against a wear plate by slinging them from a spinning center that rotates on a vertical shaft. This type of mill uses the same principle as a VSI crusher.. Tower mill. Tower mills, often called vertical mills, stirred mills or regrind mills, are a more efficient means of grinding material at smaller particle sizes, and can be used after ball mills in a

The ball mill is a cylindrical drum (or cylindrical conical) turning around its horizontal axis. It is partially filled with grinding bodies: cast iron or steel balls, or even flint (silica) or porcelain bearings. Spaces between balls or bearings are occupied by the load to be milled.

Ball mills tumble iron or steel balls with the ore. The balls are initially 510 cm diameter but gradually wear away as grinding of the ore proceeds. The feed to ball mills (dry basis) is typically 75 vol.% ore and 25% steel. The ball mill is operated in closed circuit with a particlesize measurement device and sizecontrol cyclones.

Structure Of Ball Mill. The operating principle of the ball mill consists of following stepsn a continuously operating ball mill, feed material fed through the central hole one of the caps into the drum and moves therealong, being exposed by grinding medie material grinding occurs during impact falling grinding balls and abrasion the particles between the balls.

Structure of ceramic Ball Mill: Ceramic ball mill is a horizontal cylinder rotating device, by feeding, discharging part, turning part, a transmission part (reducer, small transmission gear

#0183;#32;DEFINITON: A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering etc. 6. PRINCIPLE: A ball mill works on the principle of impact and attrition. size reduction is done by impact as the balls drop from near the top of the shell.

#0183;#32;The following will introduce the basic structure of the main components of the mill. Rotary Rotary parts include: cylinder, energysaving grinding plant grinding head (end cap and hollow shaft), linings, diaphragm plate, blocking balls circle parts. (1) cylinder

Planetary Ball Mills are used wherever the highest degree of fineness is from the classical mixing and size reduction processes, the mills also meet all the technical requirements for colloidal grinding and have the energy input necessary for mechanical alloying extremely high centrifugal forces of planetary ball mills result in very high pulverization energy and

Analysis of the structure and working principle of ball mill. Analysis of the structure and working principle of ball mill. Time: . The ball mill has a general role in production in our country in the field of industrial raw material, because of this mill is the most rapid technological development in the mining machinery equipment, but no matter how development, is the change from

WhatsApp)

WhatsApp)