Operational parameters affecting the vertical roller mill

The vertical roller mill (VRM) is a comminution device in which crushing, grinding and classification processes are combine together into a single unit operation.

WhatsApp)

WhatsApp)

The vertical roller mill (VRM) is a comminution device in which crushing, grinding and classification processes are combine together into a single unit operation.

Vertical Roller Mill ( Operator ) MSP STEEL and POWER LIMITED card_travel 1 to 5 yrs As per Industry Standards location_on Raipur (Chhattisgarh) Apply! Job Applicants: {{}} Posted on 08 Jul, 2020; Job Description o Operation of VRM raw mill, VRM coal mill, Ball mill, stacker etc.

Raw Mill Hoppers In Cement Plants. Rawmill Wikipedia. A rawmill is the equipment used to grind raw materials into quot;rawmixquot; during the manufacture of is then fed to a cement kiln, which transforms it into clinker, which is then ground to make cement in the cement mill.

In the production process, the wear of the grinding roller and the grinding ring of the vertical grinding equipment also has an effect on the particle size. In the normal operation of the mill equipment, the wear of the grinding roller and the grinding ring does not occur. However, due to the longterm work of the mill, wear will occur, and the wear will result in insufficient grinding of the material.

Nov 16, 2011#0183;#32;Process in vertical raw mill

FL has supplied the global cement industry with leading Vertical Roller Mill (VRM) designs for raw, fuel and cement grinding for several decades. The OK mill has been FLs standard cement VRM since 1993. Since its introduction, the OK mill has proven to be the most efficient cement

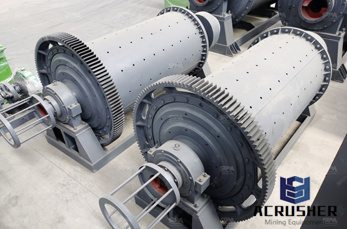

Vertical roller mill is a kind of grinding machine for cement, raw material, cement clinker, slag and coal slag. It has the features of simple structure and low cost of manufacture and use. It has the features of simple structure and low cost of manufacture and use.

Roller Mill Capacities . Stationary Roller Mill Brochure. Stationary Roller Mill Operators Manual Stationary Roller Mill Illustrated Parts List Contact the Arts Way Sales Team for more info at ! Customers are saying Quote.Person, State Quote.Person, State. View other hammermill and rollermill models gt;

Grinding and separation efficiency of vertical roller mill were evaluated. In addition to these, performance figures of vertical roller mill and conventional closed ball mill circuit were compared.

Feb 10, 2016#0183;#32;VRM vs Ball Mill for Cement Grinding. Good Days! Gentlemen, Anybody in this forum who have had some practical/extensive experience on Vertical Roller Mill being used for cement grinding? We are planning to put up a new cement grinding plant using Vertical Roller Mill(300350 TPH) and before implementing the project, we would like to

Vertical roller mill Wikipedia. Vertical roller mill is a kind of grinding machine for cement, raw material, cement clinker, slag and coal slag. It has the features of simple structure and low cost of manufacture and use. Vertical roller mill has many different forms, but it works basically the same.

To realize this project, LOESCHE will deliver the vertical roller mills. With a capacity of 500t/h, the raw mill will be applied for the grinding of cement raw material to a fineness of 12% R 90m. The six powerful cement mills, which will have a 350t/h throughput each, are installed for the grinding of cement clinker to a fineness of 3

WhatsApp)

WhatsApp)