The Basics of How Ore Processing and Recovery Plants Work

Mar 15, 2018#0183;#32;A 6500 TPD Gold amp; Silver Processing Plant will cost millions of dollars where small mineral pilot plants may cost hundred of thousands and a portable pilot plant

WhatsApp)

WhatsApp)

Mar 15, 2018#0183;#32;A 6500 TPD Gold amp; Silver Processing Plant will cost millions of dollars where small mineral pilot plants may cost hundred of thousands and a portable pilot plant

This is a video showcasing our 1 ton per hour complete, chemical free, gold ore gravity processing plant. This system is specifically designed for the small

The gold grade in the ore is /t, mainly fine particles, and little microparticles. Most of which are concentrated in the range of Natural gold is mainly embedded in pyrite, mainly inclusion gold (%), followed by cracked gold (%). Mine PreDevelopment Site Inspection for a Gold Mine. 2. Processing Plant

Jun 20, 2019#0183;#32;A new technology that delivers commercialscale, cyanidefree gold processing has been released by Australianbased company Clean Mining. The process replaces cyanide with a

#0183;#32;Gold bulls were disappointed that the price did not break through the 2,000/oz ceiling; nevertheless the current stable price run has helped to maintain a strong interest in gold projects. Gold processing has a couple of unique features.

farvic gold processing plant HFC Refrigerants (55) HST Hydraulic Cone CrusherHST series hydraulic cone crusher is combined with technology such as machinery, hydraulic pressure, electricity, automation, intelligent control, etc., representing the most advanced crusher technology in the world.

Aug 21, 2020#0183;#32;The infrastructure for a processing plant that uses cyanidation typically costs 30 million, and is therefore, a barrier to entry for gold miners with smaller deposits that do not fit into the largescale economies of gold production. Gold recovery by cyanidation is also of environmental and safety concern as it relies on the use of toxic cyanide.

Gold Processing Plants. Star Trace offers turnkey solutions for gold processing plants. Specialized in the fabrication of these machines for 25 years and this enables us to be in a leading position in the field of gold processing plant amp; equipment. We specialize in gold processing plants, gold trommel plants and portable gold trommel plants.

Taking the gold cyanidation plant with processing capacity of 100000 tons and gold grade of g/t as an example, gold CIL process can save the investment cost of 486000 than the CIP process, reduce the capital backlog of 201700, save and recycle capital of 675100 in advance excluding the cost of activated carbon. 2.

A small gold mine flowsheet is shown below together with cost data which clearly shows the results that can be obtained when handling a low grade ore by a simple process. There are many commendable features in such a set up and no complicated machines or practices are embodied in this plan. In fact, its simplicity is appealing and the results obtained prove the practicability of this

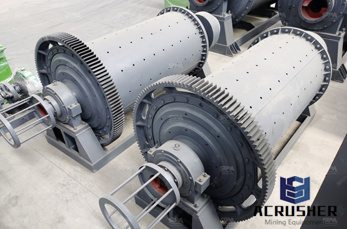

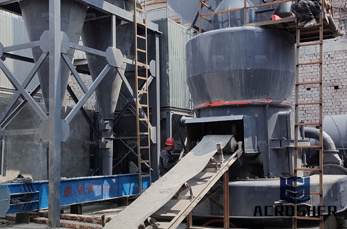

DOVE offers the most extensive and complete line of Hard Rock Processing Plants, configured with crushing, grinding and processing plant for complete cycle from rock reduction to processing and treatment circuit, designed for recovery of gold, platinum, light metals, base metals, ferrous metals, sand, gravel, and coal, from the liberated particles, with highest recovery rate and down to micron

#0183;#32;How to set up an ecofriendly gold processing plant November 7, 2019 When youve literally struck gold and are ready to start processing, its easy to turn to traditional methods to extract your gold from ore but there is a better, safer and costeffective solution.

With our rich industry experience and knowledge, we are engaged in offering high quality Gold Processing offered processing plant is designed and manufactured by our professionals as per the set market norms by utilizing best quality raw material and latest technology.

Barrick Lumwana was planning to implement their Asset Management Improvement project in Zambia. They needed a review of the current situation of the Lumwana process plant to recognise key areas of risk and opportunity which allowed them to accomplish the Life of Mine production plan of processing 25MPTA through the grinding circuit from 2020.

Gold Mine Processing Plant. GBI was initially contracted by Oceana Gold to provide 18 process tanks for a new processing plant at their Haile Gold mine located in South Carolina. M3 Engineering was assisting Oceana as advising engineer. Once on site, GBI''s crews were immediately recognized by Oceana and M3 for their excellent safety, quality

Gold ore . Prominer maintains a team of senior gold processing engineers with expertise and global experience. These gold professionals are specifically in gold processing through various beneficiation technologies, for gold ore of different characteristics, such as flotation, cyanide leaching, gravity separation, etc., to achieve the processing plant of optimal and costefficient process designs.

Used gold processing plant. Generally, a comprehensive gold processing plant is often divided into 3 stages, crushing, grinding and beneficiation. Considering the fact that distinct gold from unique location are going to be in different characteristics, the exact processing remedy will

Gold. How, Blanket, Vubachikwe, Jessie, Farvic, Fred, Freda, Antelope, Nubobs etc. Greenstones. The province has been consistently been the highest gold producing provinces of the country in the recent past. Diamonds. River Ranch, Ngulube Pipes. Limpopo Mobile Belt, Granitic terrane. River Ranch started operations in 1992 but stopped operations

Oct 21, 2020#0183;#32;A consortium of world leaders has come together to commercialise a onestopshop for collecting and analysing gold plant data in realtime a process that will revolutionise the industrys ability to measure circuit inventory and recovery in real time, move it into the digital world and whilst providing opportunity for full automation.

The gold prices used in this table and chart are supplied by FastMarkets. Where the gold price is presented in currencies other than the US dollar, it is converted into the local currency unit using the foreign exchange rate at the time (or as close to as possible). Processing, smelting and refining gold.

The Gold Processing Plant control station includes the water distribution manifold. The large barb on the left hand side is the clean water connection. Connect this to a pump capable of supplying both the clean process water near 15 L/M and the slurry water near 77 L/m (to make 30% solids at 2 tph) at 15 psi.

Zimbabwe dumps. mine.. The gold reefs in Zimbabwe processing circuit and commissioning will be completed in August. m Farvik fine grind gold plant at Farvic. SA Mining

The IGR 100 Modular Gold Processing Plant is a selfcontained fine gold recovery equipment system. It uses classification and enhanced gravity to assure you are catching the finest gold and the big nuggets. In the standard configuration material flows as follows: The miner feeds sand/gravel into the vibrating screen The screen divides your feed

Alluvial gold processing plant / 90%+ Gold Recovery Ratio Hengcheng offers complete project solutions for Alluvial Gold Processing Plant. We are one of the leading project suppliers for Alluvial Gold Wash Plant Equipment and we work closely with our customers to fulfill their specific needs for customized package solution.

WhatsApp)

WhatsApp)