Coal preparation plant Wikipedia

Biocoal: A renewable and massively producible fuel from

WhatsApp)

WhatsApp)

Biocoal: A renewable and massively producible fuel from

Biocoal. Biocoal is a coal which is similar to fossil coal. Difference stems from the fact that biocoal is produced artificially from biomass by means of hydrothermal carbonisation (HTC) technology and compared to fossil coal it offers several significant advantages.

With the idea of supplying clean energy to utility companies in Nordic countries and Central Europe, the biocoal plant will rely on a torrefaction technology developed by a Dutch company called

The QC Dept. at White Coal Project has many tasks, with quality of the plant project. Review all production records for accuracy amp; entirety before Mfg. Whitecoal Machinery produce tons of Bio(White) coal ever growing quality assurance globally.

#0183;#32;Development of renewable energy is essential to mitigating the fossil fuel shortage and climate change issues. Here, we propose to produce a new type of energy, biocoal, via a fast pyrolysis coupled with atmospheric distillation process. The high heating values of the asprepared biocoals from the representative biomass are within to MJ kg1, which are comparable to that of the

#0183;#32;Pixel Studios created a comprehensive 3D Visualization (visual walkthrough) which features every step involved in procuring coal, stage by three di...

For sales information and prices, contact our processing facility in Decker, MT at (406) . Also, call us to know our business hours. For quality coal, call (406) .

A coal preparation plant (CPP; also known as a coal handling and preparation plant (CHPP), coal handling plant, prep plant, tipple or wash plant) is a facility that washes coal of soil and rock, crushes it into graded sized chunks (sorting), stockpiles grades preparing it for transport to market, and more often than not, also loads coal into rail cars, barges, or ships.

Bio coal manufacturing process. Bio coal supplier,bio coal manufacturer,bio coal Royal Bio Coal. Throughout the manufacturing process, we take various measures so as to ensure high quality standards. All the agro and other products are produced in More details Get Price.

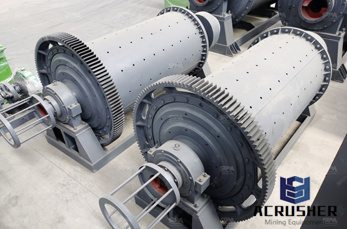

Coal processing has two forms, here descripe flow chart of coal processing plant: Industrial process is the coal after the coal crusher, with the belt conveyor to quantitative feeder, to pressure the ball machine feeding by quantitative feeder uniform, sometimes need to improve the coal briquette strength, therefore, quantitative feeder and intermediate pressure ball machine can also add

We have the ability to provide superior solutions through our global knowledge of the coal industry combined with our strength and expertise in the minerals processing industry. Our aim is to deliver superior coal process solutions for our clients big or small, regardless of the location.

Bio coal is a replacement for oil or coal, firewood; and can be used as a solid fuel in boilers, furnace, oven, heaters etc in industrial plants. A popular biomass briquette takes a waste produce such as sawdust, groundnut shells, cotton stalk, castor seed shells etc.; compresses it and then extrudes it to make a reconstituted log that can replace firewood and coal.

#0183;#32;Taking a coal washing plant in Indonesia as an example, the coking coal preparation plant with an annual processing capacity of 4 million tons can increase the processing capacity per hour to more than 700 tons, and the power consumption, media consumption, fuel consumption, and water consumption are all reduced.

The efficient design of processing plants which combine various coal based technologies in order to maximize the effectiveness of coal utilization is considered. The technical, economical and ecological virtues which compound plants for coal conversion offer are assayed. Twentytwo typical processes of coal conversion and product refinement are selected and described by a standardized method

WhatsApp)

WhatsApp)