Cement Plants located in Iraq The Global Cement Report

Cement Plant Location Information for Iraq. Cement plant locations and information on Iraq can be found below. For full access to the database, purchase The Global Cement Report, 13th Edition.

WhatsApp)

WhatsApp)

Cement Plant Location Information for Iraq. Cement plant locations and information on Iraq can be found below. For full access to the database, purchase The Global Cement Report, 13th Edition.

Cement manufacturing is a complex process that begins with mining and then grinding raw materials that include limestone and clay, to a fine powder, called raw meal, which is then heated to a sintering temperature as high as 1450 #176;C in a cement kiln. In this process,

CEMENT MANUFACTURING A WET PROCESS WITH THE FLOW DIAGRAM. In the wet process, 1) The raw limestone from quarries is first crushed to small size fragments. Then it is mixed with clay or shale in ball or tube mill and ground to form a slurry of a fine consistency with the addition of water.

Lucky Cement''s Iraqi clinker plant set for December startup 26 October 2020, Published under Cement News Lucky Cement Ltd of Pakistan has set a target date of 20 December 2020 for the startup of its greenfield clinker unit, in Samaw, Iraq. Lucky Cement ''s Chairman, Muhammad Yunus Tabba, and CEO, Mohammad Ali Tabba, informed the Pakistan Stock Exchange (PSX) in a notification of the

Containerized Industrial Reverse Osmosis Plant for Cement Manufacturing 380,000 Iraq (1 review) Request pricing. Cement production requires water as the key binding ingredient through the process of hydration. The water to cement ratio is crucial to determining the success of the cement by producing strong and durable consistency.

Methods of cement manufacturing 1 Wet process ___ grinding and mixing of the raw materials in the existence of water. 2 Dry process ___ grinding and mixing of the raw materials in their dry state. The process to be chosen, depend onthe nature of the used raw materials.

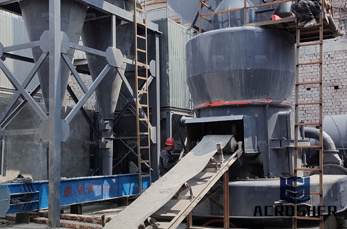

The cement manufacturing plant can be divided into five steps: Crushing amp; prehomogenization: cement crusher crush limestone and other materials and stacker and reclaimer homogenize them.; Raw material preparation: use cement mill to process materials into required sizes for cement clinker production.; Clinker production: In the cyclone preheater system, the raw material powder exchange heat

#0183;#32;P ortland cement is by far the most common type of cement in general use around the world. This articles looks at the cement manufacturing process in 4 steps. Step 1: Mining. The first step of Cement manufacturing process is to quarry the principal raw

Water plus cement plus aggregates. The formula seems simple, but the reality of concrete manufacturing is far more complex. The development of formulas for concrete requires very advanced scientific skills. The quality of the cement and aggregates, the dosage and the proportions are just some of the variables that influence the properties of

#0183;#32;Iran: Cement production rose by % yearonyear to in the first half of the local calendar year that started in March 2020 from in the same period in the previous year. The sector exported of cement with a value of US128m to 28 countries according to the Mehr News Agency. India, Afghanistan, Russia, Iraq, Qatar, Kenya, Kuwait, Sri Lanka, Pakistan, Armenia, Turkmenistan

The CW Group Research reports provides an indepth and dataoriented analysis of the cement market in Iraq. The report details cement tonnage volume and price trends in Iraq and provides a forecast through 2017 and the following 5 years.

Cement manufacturing: components of a cement plant. This page and the linked pages below summarize the cement manufacturing process from the perspective of the individual components of a cement plant the kiln, the cement mill etc.. For information on materials, including reactions in the kiln, see the '' Clinker '' pages.

Saman Cement Plant is invested by Saman Cement Co., Sinoma International Engineering was selected as EPC contractor for the project. The plant, located in Iraq, Al Mothanna District, 38Km west of Samawa City, consists of two parallel production lines with a capacity of 2 million tons/year.

Karbala Cement Plant Provides Food Baskets to the Community . Our Products. As Lafarge Iraq, we provide building materials solutions for construction projects ranging from residential to infrastructure projects with our countrywide operations and distribution network.

#0183;#32;The cement manufacturing process involves several key steps, including preparing the raw materials, grinding the materials together, heating the newly formed clinker in a kiln, and finishing the cement with fine of the main ingredients used to make cement include limestone, clay, shale, iron, and manufacturing techniques will use either wet or dry grinding, but

WhatsApp)

WhatsApp)