How gold is produced YouTube

This video was produced by Newmont Mining Corporation and gives a general overview of gold mining in Nevada from extraction to reclamation.

WhatsApp)

WhatsApp)

This video was produced by Newmont Mining Corporation and gives a general overview of gold mining in Nevada from extraction to reclamation.

May 06, 2019#0183;#32;It''s only accessible today because of asteroid bombardment. Theoretically, it''s possible to form gold by the nuclear processes of fusion, fission, and radioactive decay. It''s easiest for scientists to transmute gold by bombarding the heavier element mercury and producing gold via decay.

Jun 17, 2020#0183;#32;Gold Extraction from Mines . Gold and silver are both extracted from the mines using the cyanidation process. This process is achieved by dissolving gold or silver in either a potassium cyanide or sodium cyanide solution. Mining companies also incorporate the use of a technical extraction process in the extraction of gold.

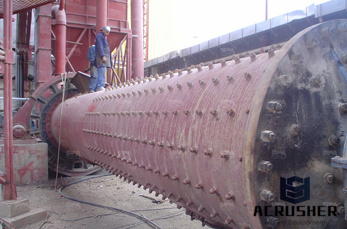

Extracting gold from the mined rock is a complicated process. The collected rocks need to be broken down into smaller chunks this is achieved at a mill where machines known as crushers reduce the rock to gravel. The LT1110 Mobile Impact Crusher from Pilot Crushtec. Image source: Pilot Crushtec.

However, gold is readily dissolved in a number of solvents, including oxidizing solutions of hydrochloric acid and dilute solutions of sodium cyanide. Gold readily dissolves in these solvents because of the formation of complex ions that are very stable. Gold (Au) melts at a temperature of 1,064#176; C (1,947#176; F).

Extracting Gold | HowStuffWorks

Gold cyanidation (also known as the cyanide process or the MacArthurForrest process) is a hydrometallurgical technique for extracting gold from lowgrade ore by converting the gold to a watersoluble coordination is the most commonly used leaching process for gold extraction.. Production of reagents for mineral processing to recover gold, copper, zinc and silver represents

Several processes can then be used to separate the gold from the ore. The most common techniques in the United States use cyanide in various ways. In one, the ground ore is put into a tank containing a weak cyanide solution and zinc is added. The zinc causes a chemical reaction which separates the gold from the ore.

Leaching dissolves the gold out of the ore using a chemical solvent. The most common solvent is cyanide, which must be combined with oxygen in a process known as carboninpulp. As the cyanide and oxygen react chemically, gold in the pulp dissolves. When workers introduce small carbon grains to the tank, the gold adheres to the carbon.

The lifecycle of a gold mine. People in hard hats working underground is what often comes to mind when thinking about how gold is mined. Yet mining the ore is just one stage in a long and complex gold mining process. Long before any gold can be extracted, significant exploration and development needs to take place, both to determine, as accurately as possible, the size of the deposit as well

The final category of gold mining is the processing of Gold ore. This method is largely becoming deprecated as the yield of Gold is often very low and the environmental impact and costs of the operation are substantial. The Gold ore is finely crushed rock or earth containing trace amounts of Gold which are extracted using a chemical process.

Unreactive metals such as gold are found in the Earth''s crust as uncombined elements. However, most metals are found combined with other elements to form compounds. An ore is a rock that contains

When the diamondrich depth is reached, the raw material extracted from the ground is then transported to a special screening plant for further processing. Theres another form of alluvial mining called artisanal mining. In essence, it is basically the same method employed by gold diggers which involves the screening and straining of mud.

Mar 29, 2020#0183;#32;Gold is processed by cyanide milling, a chemical procedure that separates 95 to 98 percent of the gold from raw mined ore. It is then refined to

When the cupel is heated, the lead seeps out through the porous holes in the cupel, leaving behind just the gold in a beadlike shape. This bead of gold is known as the prill. To separate the gold from the silver, the refiner places the gold bead in nitric acid or a combination of hydrochloric and nitric acids.

In this Instructable, I will show you how to extract gold from computers using products most people have lying around in their homes. The way I extract the gold is relatively straightforward and pretty easy, but the chemicals used are very dangerous and should not be performed without proper knowledge and equipment. This process is not supposed to be lucrative.

Gold is processed by cyanide milling, a chemical procedure that separates 95 to 98 percent of the gold from raw mined ore. It is then refined to the gold standard purity, according to Mineweb. Heap leaching is a less expensive method of gold extraction, but it is a longer process and it recovers less gold than the cyanide milling process.

Jun 17, 2020#0183;#32;Cyanidation is a method used in the extraction of gold from its ore. This extraction is done by converting the gold to a watersoluble form. The cyanidation process of gold extraction or the use of cyanide is the most common leaching process, used in the extraction of gold from its ores. Some countries do not approve of this method of gold extraction because of the poisonous nature of the

Water is then added to the powder to produce a pulp, which is run through a series of leaching tanks. Using a chemical solvent, usually cyanide combined with oxygen, the gold is extracted from the pulp inside these tanks; but it is still not pure gold. This process is known as carboninpulp. The result is gold that is attached to carbon.

The two gold refining methods most commonly employed to derive pure gold are: the Miller process and the Wohlwill process. The Miller process uses gaseous chlorine to extract impurities when gold is at melting point; impurities separate into a layer on the surface of the molten purified gold.

Sep 12, 2017#0183;#32;The process used to extract gold involves strategically drilling and blasting rocks. Plans laid out by engineers and geologists prior to mining take a lot of preparation and often show the precise position of the gold within the rocks. As a result of this, miners are able to extract large quantities of goldladen rock, referred to as the ore.

Gold extraction process is a combined process of various gold extraction methods (amalgamation, gravity separation, flotation, cyanidation) to extract gold from goldbearing rocks. The selection of the gold extraction process is mainly based on the nature of the ore and the requirements for the product form.

WhatsApp)

WhatsApp)