(PDF) Structural response to rod mill vibration

rod mill, foundation, vibrations, soil springs, dynamic analysis, structured response, dynamic amplitude ratios. Une ttude a CtC mente dans le but de determiner l''effet des vibrations causCes par

WhatsApp)

WhatsApp)

rod mill, foundation, vibrations, soil springs, dynamic analysis, structured response, dynamic amplitude ratios. Une ttude a CtC mente dans le but de determiner l''effet des vibrations causCes par

Vibration is a mechanical phenomenon whereby oscillations occur about an equilibrium word comes from Latin vibrationem (quot;shaking, brandishingquot;). The oscillations may be periodic, such as the motion of a pendulumor random, such as the movement of a tire on a gravel road.. Vibration can be desirable: for example, the motion of a tuning fork, the reed in a woodwind instrument or

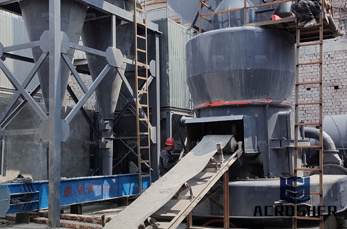

Metallurgical ContentRod Mill Capacity and Sizing TableROD MILL SPECIFICATIONSROD MILL CAPACITIESROD MILL General ArrangementDimensionsPERIPHERAL DISCHARGE ROD MILLSWet Grinding ROD MILLINGDry ROD MILL GrindingCENTER PERIPHERAL DISCHARGE ROD MILL Rod Mill Working Principle amp; ComponentsRod Mill Grinding The Steel Head Rod Mill (sometimes call a bar mill

Working Principle. The high efficiency vibration mill is mainly composed of the base frame, the body frame, the acoustic enclosure, the body, the grinding cylinder, the vibrator, the lining plate, the spring support, the grinding medium and the driving on the power, drive the motor through the flexible coupling to drive the vibrator to rotate, generating enough excitation force, Keep the grinding

Vibration Tube Mill Grenzebach Maschinenbau . Vibration Tube Mill. Grenzebach BSH Vibration Tube Mills operate according to the vibromill principle,

Fig. shows the torsional vibration of a cantilevered and clampedclamped (5, 5) SWCNT. The fundamental frequencies can be predicted well by the rod model for long SWCNT. It is necessary to use the nonlocal rod model to predict the natural frequencies for short SWCNT, such as nm long.

2. Working principle of the vibration grinding mill. The vibration grinding mill / ball mill is a key equipment to grind the crushed materials, and the ball mill is widely used in powdermakingThere are two kinds of ball mill, grate type and overfall type due to different ways of discharging material.

Vibration mill is the use of vibration principle to achieve Mobile Crusher Portable Crusher solid material grinding. according to different structures, vibration mill can be divided into monocular and binoculartype vibration mill mill two vibration. below with binoculars vibration mill for example, details the structure of a vibration mill. binoculars vibration mill by the body chassis

#0183;#32;3/4quot; x quot; tubes acting as rods in a 250mm x 195ID jar, cardboard acting as an end plate at the rear to test if the rods roll in a uniform manner even thoug...

principles of rod mill CPY manufacturers. kinds of minerals vibration rod mill principle vibration rod mill principle, Here are pictures of the Taig Micro Lathe and Taig Milling Machine,, Part 1Basic, basic principles of, Contact supplier. rod mill work index classification. Read More

According to the rod mill working principle, we can see that the rod mill is featured with the following advantages: 1. The discharge size is uniformity and high yield. 2. The types are various and reasonable choice depends on the material. 3. Rod mill has dry and wet two forms and needs according to their actual situation to choose.

Solitel#174; operates on the principle of detecting the dampening effect when solids are brought into contact with the vibrating rod. Normally, SOLITEL vibrates at a frequency of approximately 350 Hz. This vibration is created by exciting the transmit piezoelectric crystal attached at the base of the outer rod. The piezoelectric crystal converts electrical energy to mechanical (vibratory) energy.

vibration rod mill principle wildpeppersf. The working principle of mobile impact crusher ball mil,jaw crusher, vibration rod mill principle,Mobile impact crusher is a kind of crushing machinery broken material by using the impact and its widely used in mining, road, ralway, chemical industry, etc mobile impact crusher is welcomed by customers both home and abroad, because .

Vibration rod mill principle vibration tube mill principles Grinding Mill China This paper primarily introduces the principles and the characteristic of rotary ultrasonic g In this paperon the Live Chat Working principle of rod millShanghai Minggong Ball Mill Get Price Working Principle Of Vibrator Motor Crusher Mills .

vibration theory. If Plt;P cr n then Y n(t) = A ncos nt+B nsin nt, (9) where n = #177;#175; n p 1P/P cr n, (10) and simple harmonic motion results. Any perturbation will induce oscillatory motion about equilibrium. The response neither grows or decays.

Rod Mill Operations. Designed to accept feed from a secondary crusher. Feed particle size = 6 25 mm. Peripheral speed = 85 146 m/min (280 480ft/m in) Reduction ratio = 2 20 depending on material. Typically R = 8. Rod Mill Charge: Typically 45% of internal volume;

ADVERTISEMENTS: After reading this article we will learn about: 1. Meaning of Rolling 2. Process of Rolling 3. Principles 4. Load and Power Requirement 5. Lubrication 6. Defects. Meaning of Rolling: The process of shaping metals into semifinished or finished forms by passing between rollers is called rolling. Rolling is the most widely used metal []

vibration rod mill principle Crusher Price. Raymond Mill,Raymond Grinding Mill,Raymond Grinder,Milling When the Raymond Mill is working, firstly, raw material is crushed by rock the electromagic vibrating

WhatsApp)

WhatsApp)