Silica sand washing plant Australia YouTube

#0183;#32;A 100tph silica sand washing plant we installed at Tooperang Quarry in Australia. The glass sand being produced is being used by OI (Owens Illinois) in their A...

WhatsApp)

WhatsApp)

#0183;#32;A 100tph silica sand washing plant we installed at Tooperang Quarry in Australia. The glass sand being produced is being used by OI (Owens Illinois) in their A...

Silica sand washing plant equipment and process. Washed sand is construction sand that is obtained after the natural silica sand is washed by a silica sand washing plant and meets the construction standards of various places. Both artificial sand and natural sand contain certain impurities.

#0183;#32;Silica processing methods. Posted: Silica sand is much demand for glass producing, especially with the high pureness. Silica processing methods are mainly through crushing, sieving, washing and drying natural quartz stone to get finished products for widely used in glass, casting, ceramics and refractory materials, metallurgy, construction, chemicals, plastics, rubber,

Silica Sand Processing amp; Sand Washing Plant Equipment

Silica sand low in iron is much in demand for glass, ceramic and pottery use, and for many of these applications clean, white sand is desired. Impurities such as clay slime, iron stain, and heavy minerals including iron oxides, garnet, chromite, zircon, and

Silica sand washing plant equipment and process. Washed sand is construction sand that is obtained after the natural silica sand is washed by a silica sand washing plant and meets the construction standards of various places. Both artificial sand and natural sand contain certain impurities.

washing process for silica sand theboxalmelo . detail washing process of silica sand vanmouriktielnl. Silica Sand Processing Equipment Silica Sand Washing, Silica sand ore usually contains iron, sand, clay silica, and other heavy minerals, in order to get required grade silica sand, firstly need to wash clean the clay, then remove iron and other heavy minerals, so the silica grade will

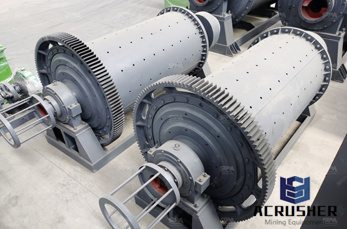

Silica sand washing plant mainly includes: quartz stone crushing and sand making, washing, grading, desliming, scrubbing, magnetic separation, flotation, acid leaching and other processes to remove the small amount or micro amount of impurities in silica sand and obtain refined silica sand or highpurity silica sand for glass, ceramics, construction, chemical and other industries.

Silica Sand Process Flow For common industrial silica sand washing plant, try to choose a relatively simple technological process to reduce the cost of mineral processing and purification. ScrubbingDeslimingMagnetic Separation process is recommended to meet the quality requirements of silica sand.

silica sand washing machine: silica sand washing machine are an effective way to wash, dewater, deslime and control the bottom end of the gradation. A large pool area provides maximum retention of desirable product sizes, while a rising current system floats off the excess fines. advantages: Read more

Sand washing and screening is the important part during the sand process, JXSC recommend you 3 types of Silica Sand Washing Machine for different grain size silica sand washing.. 1 Log Washer. The log washer/ sand washer machine thoroughly scouring, breaks down, and cleans the toughest materials.

Silica sand plant process silica sand form its raw state into qualified products. The processes always include: screening, washing, dewatering, classifying and waste management etc

#0183;#32;XSD series Sand Washing Machine (sand washer)is a kind of wheeled washing equipment, mainly used in building site, gravel plant, concrete dam building site of hydropower station, casting70 sand

Silica Sand Mining introduces. Foundry silica sand is the quartz as the main mineral composition, particle size of mm to mm refractory particles, according to the mining and processing methods of different can be divided into artificial silica sand and sand washing, sand washing, selection of natural silica sand such as sand (flotation).

WhatsApp)

WhatsApp)