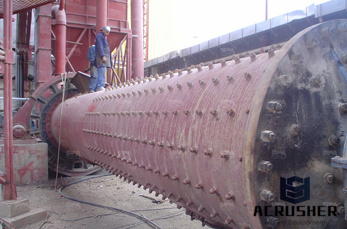

gauge mechanism for ball mill machines

Ball mill (up) and schematic of its main action mechanisms (down) In Fig. the working principle and main action mechanism of ball milling are presented. Viewing this image requires a subscription.

WhatsApp)

WhatsApp)

Ball mill (up) and schematic of its main action mechanisms (down) In Fig. the working principle and main action mechanism of ball milling are presented. Viewing this image requires a subscription.

The speed of the rotation will be control by the regulator and the jar will keep rotating until the material inside become a very fine powder. To ensure the stability of the mini ball mill, a ball...

The working principle of ball mill Meetyou Carbide

Ball mills tumble iron or steel balls with the ore. The balls are initially 510 cm diameter but gradually wear away as grinding of the ore proceeds. The feed to ball mills (dry basis) is typically 75 vol.% ore and 25% steel. The ball mill is operated in closed circuit with a particlesize measurement device and sizecontrol cyclones.

mechanism of working of ball mill,CGM closed frame type and open type mechanism, of ball mill Ball Mill Working principle . Get Price. ball mill avilable in trichy address. ball mill working with workersCrusher Manufacturer . More information of trichy building mills for sales CGM grinding plant grinding machines are available in a .

The Working Principle of Hammer Mills (Stepbystep Guide) A hammer mill is an essential machine in the pharmaceutical and food processing industries. You can use it to crush, pulverize, shred, grind and reduce material to suitable sizes. Even though there are many types of hammer mills, the working principle is still the same.

Dispersion Mechanism Of Ball Mill. The grinding mechanism of ball mill and vibration mill is expressed in terms of probabilities overall treatment of milling mechanism in this paper is satisfactory chat now ultrafine grinding mechanism of inorganic powders in a stirred ball..ball mill wet grinding system cameroon. Live Chat

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many processes. There are many different types of mills and many types of materials processed in them. Historically mills were powered by hand, working animal, wind or water. In modern era, they are usually powered by electricity. The grinding of solid materials

Ball mill working mechanism of jaw plate of jaw crusher the working mechanism of jaw crushers is composed of moving jaw and fixed jaw working jaw plates and fixed jaw sheet bear huge crushing force and material friction, easy to wear out, in order to protect the jaw plates

Mechanism Of Working Of Ball Mill Mechanism Of Working Of Ball Mill. Roller mill working mechanism products as a leading global manufacturer of crushing read more fl energyefficient grinding mill designed for a designed for the most energyefficient and reliable grinding of all cement types this roller mill is much more than ok with more than 150 mills sold the ok cement

To be chosen according to the grinding material, material is composed of a ball mill feed end of the hollow shaft is arranged in the tube body, when the ball mill cylinder rotation time, grinding body due to inertia and centrifugal force, the effects of friction, making it attached to the cylinder liner on the cylinder body away, when taken to the height of a certain, because the action of its own gravity and dropped, the

To be chosen according to the grinding material, material is composed of a ball mill feed end of the hollow shaft is arranged in the tube body, when the ball mill cylinder rotation time, grinding body due to inertia and centrifugal force, the effects of friction, making it attached to the cylinder liner on the cylinder body away, when taken to the height of a certain, because the action of its own gravity

Mechanism Of Working Of Ball Mill. Oct 10 The drum of the ball mill Pic. 1 is a hollow cylinder of steel lined inside with armor lining plates which protect it from impact and friction effects of the balls and the grinding material.

How ball mills work A ball mill grinds material by rotating a cylinder filled with media typically metallic or ceramic balls mixed with a continuous flow of feed and recycled material At slower rotational speeds the grinding media creates a cascade motion where the media is

May 22, 2019#0183;#32;The ball mill consists of a metal cylinder and a ball. The working principle is that when the cylinder is rotated, the grinding body (ball) and the object to be polished (material) installed in the cylinder are rotated by the cylinder under the action of friction and centrifugal force. At a certain height, it will automatically fall and impact and grind the material in the cylinder to grind the material.

mechanism in ball mill. Feb 08, 2017#183; The operating principle of the ball mill consists of following a continuously operating ball mill, feed material fed through the central hole one of the caps into the drum and moves therealong, being exposed by grinding media.

Metallurgical ContentBall Mill Capacity VS Rod Mill CapacityWorking Principle amp; OperationRod Mill Capacity TableBall VS Rod Mill ConversionTypes of Mill DischargeBall Mill Trunnion and Mill Grate DischargePeripheral Grinding Mill DischargeLoad Capacity of Trunnion BearingsBall Mill amp; Rod Mill LinersGrinding Mill GearsGrinding Mill DrivesBall Mill Grinding CircuitBall Mill SpecificationsAll

In a continuously operating ball mill, feed material fed through the central hole one of the caps into the drum and moves therealong, being exposed by grinding media. The material grinding occurs during impact falling grinding balls and abrasion the particles between the balls. Then, discharge of ground material performed through the central hole in the discharge cap or through the grid (mills with center

Mechanism of working of ball mill knock mining of ball mill used in paint analysis of abrasion mechanism of grinding media in a the mill used in this work was a planetary ball mill frisch pulverisette7 the mill pot is made of stainless steel and its inner diameter and height are 40 and 38 mm respectively the material of the

Jun 20, 2019#0183;#32;Learn how a ball mill works, all of its main parts and some of its design features! This 3D animated video allows you to see all the internal parts of a ball...

Jan 11, 2016#0183;#32;A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it can be rotated along its longitudinal axis. The balls which could be of different diameter occupy 30 50 % of the mill volume and its size depends on the feed and mill size.

WhatsApp)

WhatsApp)